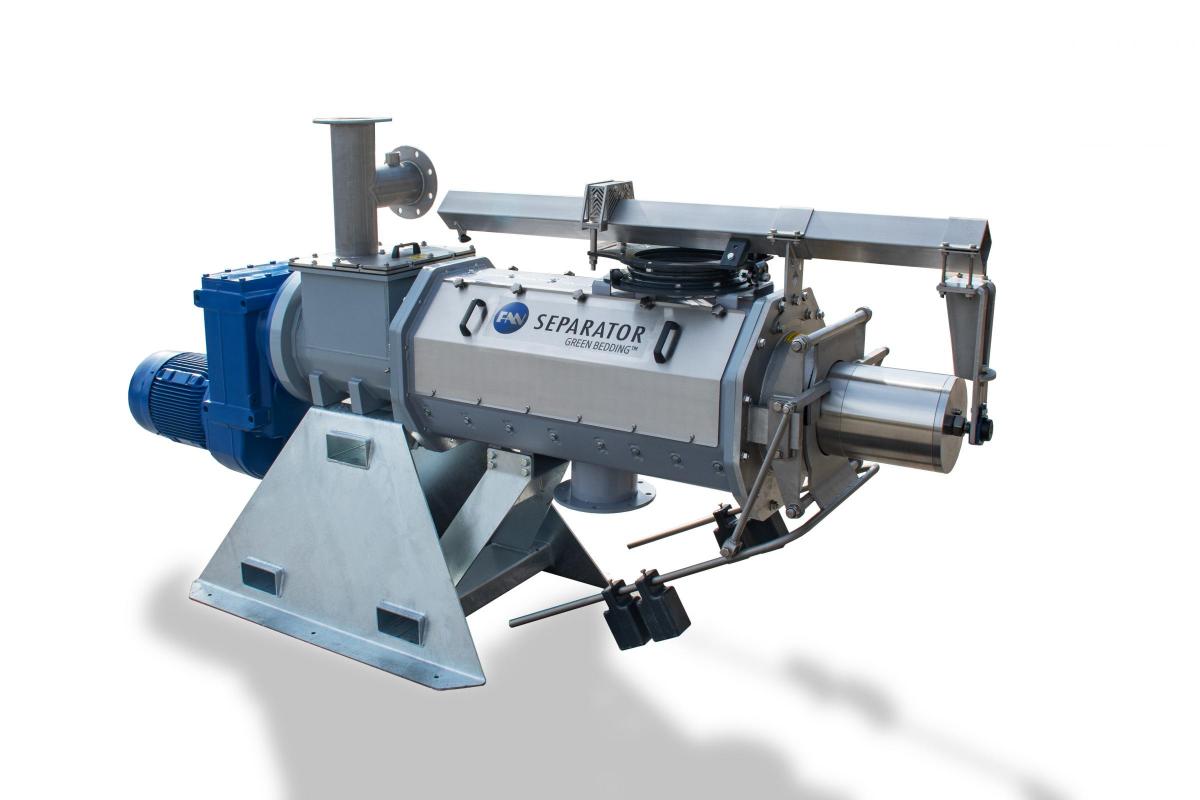

In a move toward sustainability, FAN Separator introduces its latest press screw separator, the PSS 8, expanding its lineup with a machine boasting the capacity to replace two or three smaller counterparts. The company is claiming this brings energy savings and reduces labour and the need for additional equipment.

The substantial output of the PSS 8, reaching 65 cubic meters per hour, is aimed as an ideal solution for large dairy farms seeking efficient management, storage, and field application of cow slurry. Moreover, it proves beneficial for extensive biogas production.

The separation of solids and liquids in farm slurry opens avenues for effective processing and reuse. The solid material can be transformed into compost or used as bedding, especially for dairy cows in cubicle sheds. Simultaneously, the liquid fraction becomes more manageable, facilitating storage and field spreading as fertilizer, including the option of a 'dirty water' irrigation system.

READ MORE | Discover urea-based fertiliser advantages unveiled at LAMMA

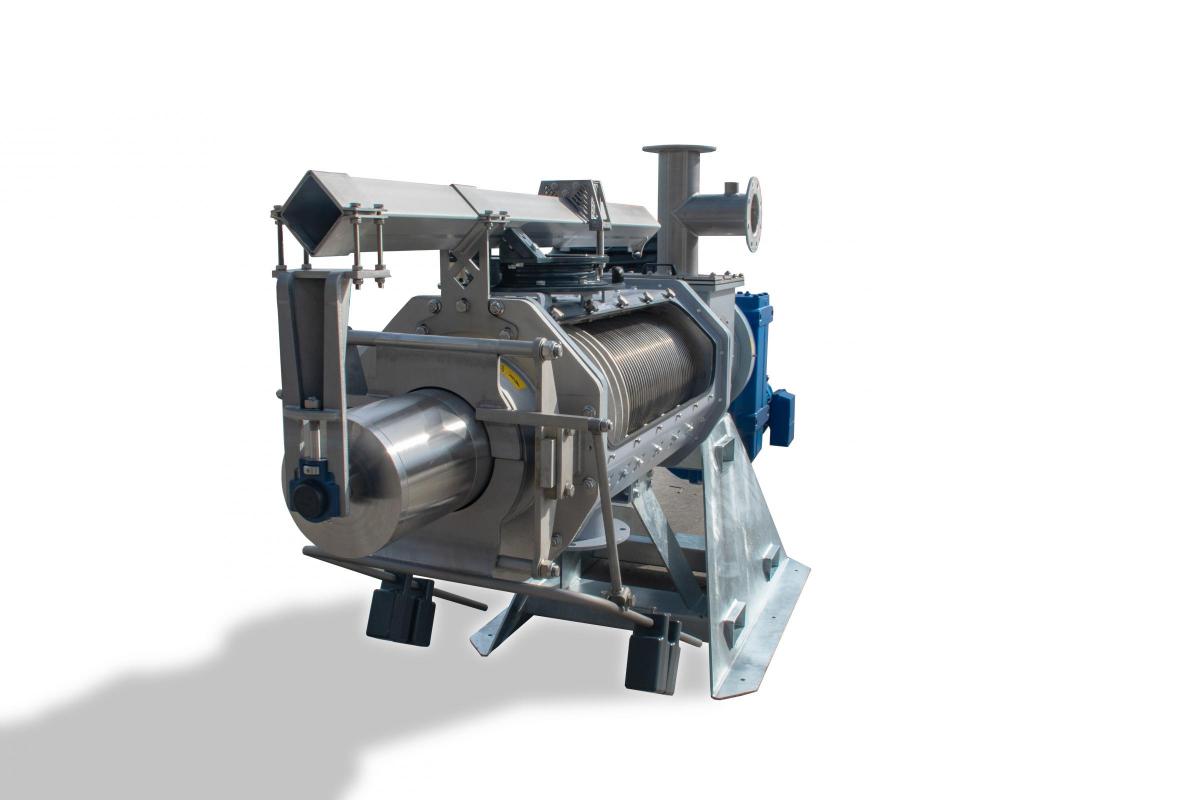

With dimensions measuring 3.6m x 0.9m and a height of 1.3m up to the inlet, the PSS 8 separator is designed for continuous use on large farms, embodying robustness. The proven FAN press screw concept persists, with enlarged components including a 2200mm long and 350kg heavy auger, supported by a head bearing. The generously sized 400mm diameter screen ensures efficiency. A 30kW electric motor, operating at 400V/50Hz, propels the built-in auger.

When handling cattle manure with a dry matter content of 7 to 9%, the PSS 8 achieves a throughput of up to 65 cubic meters per hour. Adjusting the moisture content or dryness of the extracted solids is possible through a patented output regulator, controlled by the number and position of counterweights. Users can expect unwavering output and high-quality material, maintaining a consistent dry matter content of up to 36% in the solids throughout its entire operational life.

READ MORE | Highly anticipated new Massey Ferguson on display at LAMMA

Following the tradition of the entire FAN product range, the PSS 8 is constructed with care, featuring wear-resistant reinforcement in the screw and stainless steel parts in contact with slurry, ensuring an extended lifespan. The floating screen bearing, coupled with continuous cleaning by the screw, minimises wear even during prolonged operation. Convenient access further facilitates quick and easy routine maintenance.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here