WITH the current challenges facing arable farmers with loss of chemicals products, precision in seed drilling has become a real priority.

Precise seed metering and exact depth placement plays a useful part in targetting high yields and part-area, site-specific sowing and automatic switching on and off at the headland are increasingly gaining in importance.

Plus, with a renewed focus on the simultaneous application of several seed types, or fertiliser as well as the addition of companion plants and undersown crops, flexibility at the drill is increasingly important.

That's what Amazone's new Cirrus-CC universal sowing combination hopes to achieve. It is equipped with a twin outlet, pressurised hopper and a second conveying system that feeds the supplementary FerTeC single-disc fertiliser coulters.

Add the new GreenDrill 501 universal catch crop seeder box to the set-up and then up to three different materials can be applied simultaneously, independently of each other andat different placement depths in the so-called triple-shoot process.

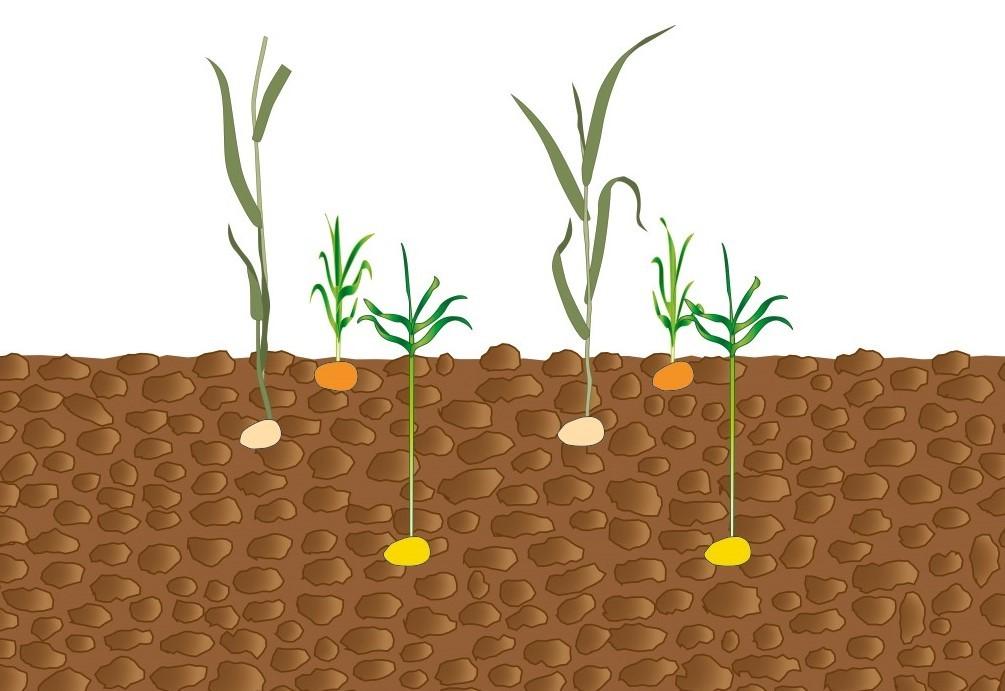

This seeding system provides the user with a variety of agronomical benefits. Companion plants and undersown crops are beneficial for weed suppression and erosion control as well as biodiversity. Triple-shoot enables the placement of three different seed types in one pass – for instance, rape sown in the upper horizon as the main cash crop via the TwinTeC+ double disc coulter; field beans placed deeper via the FerTeC single disc coulter and serve as a means of fixing nitrogen; and companion plants sown on the surface via the GreenDrill seed baffle plates.

Alternatively, two seed types with fertiliser can also be applied at three different levels. In this case, a small quantity of fertiliser is placed directly by the grain via the sowing coulter in the single-shoot process to support seedling development.

Fertiliser can also be placed in the deeper soil horizon between the seed rows via the FerTeC single-disc coulter by double-shoot, in order to stimulate root growth.

This offset placement means that fertiliser can be used more precisely ensuring a more comprehensive supply to the plant. A companion plant is sown by the triple-shoot method via the GreenDrill, to give flexibility in combining seed and fertiliser.

The metering units in the twin outlet hopper and the GreenDrill can be calibrated by means of an optional TwinTerminal 3.0 fitted on the machine, or via the mySeeder App.

With this, application rates and speeds are clearly displayed on the Amazone AmaTron 4 ISOBUS terminal and the driver can change the seed rate from the tractor seat during work without any problems.

When using application maps, all three hoppers can be individually controlled using the MultiBin function and the application rates of the respective materials independently varied in part-area zones. Automatic GPS-Switch provides delayed switching at the headland for each material via the MultiBoom function.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereComments are closed on this article