Few would believe top yields and improved levels of efficiency are possible with a flying herd, but you only have to look at AgriScot Dairy Farm of the Year winners, the Watson family’s commercial unit at Laigh Tarbeg, to see that nothing could be further from the truth.

Such has been the continued precision to cow health, comfort, nutrition and hygiene over the years, that the family – Hugh and Moira Watson, daughter Elaine and son Alastair, his wife Karen and their young family of Katie and Alison – have seen rolling 305-day milk yields rise to in excess of 12,000kg in recent years.

Average daily milk yields recorded for the competition – sponsored by IceRobotics – and even yet stand at 42.5kg with butterfat and protein percentages also a very respectable 3.76% and 3.16%, with somatic cell counts at 110.

Just as impressive, if not more so, is the fact that attention to detail during the transition period has seen the number of females in calf at 100days in milk rise to 49% thereby helping to reduce the calving interval to 397 days.

“We have always concentrated on the milking cows when we didn’t have the shed space or the acres to rear youngstock,” said Hugh who initially was milking 170 cows on the 180-acre unit at Laigh Tarbeg, before buying the 120-acre nearby 100-cow dairy unit at Plotock – lock, stock and barrel – in 2004.

In those days Hugh and Alastair were milking the cows through two herringbone parlours, which saw total yields for 250 cows gross 1.6m litres.

With extra staff required to milk these cows when both were on separate units, it was not long after that the decision was made to buy two Lely robot milking machines with the eventual aim to milk all the cows through the one unit on robots.

Now, all cows are milked through five Lely robot machines and total milk yields have soared to 3.1m litres from the same number of cows. Over the past year, the team has taken on assistance from young Alistair Middleton too.

“Lactations have doubled and our cows are fitter than ever because we have got more time to spend with them and address any issues,” said Alastair who pointed out that milk yields peak quicker and last longer when cows are milked through a robot.

Backing up these statements is the fact that on the day of our visit, the herd had five cows giving more than 70kg per day and 20 yielding in excess of 60kg of which one was 190days in milk.

Their most impressive female to date has been a Perryston heifer bought at Ayr Mart, which the day of our visit, had produced 14,000kg at 265days and is still producing 59.6kg at 97days in calf. Her projected 305-day yield is now 15,667kg.

Equally notably, their top cow, a Kepculloch-bred female bred by Robert Steel, boasts a top yield at 84kg at 75days in milk.

Contrary to popular opinion, flying herds do not necessarily see increased levels of disease either.

“We’ve only had one problem in all the time we’ve been buying in milking heifers and that was a case of BVD, but we do know where our females are coming from and only buy from 14-16 tops herds in South-west and Central Belt of Scotland,” said Hugh.

Admittedly, most come from conventionally, parlour milked herds, but training them to be milked through a robot is no different, Hugh said, with most getting into the swing of it by the second day.

“Robotic cows are really quiet but then they are never stressed queuing up to get milked or to be fed. They are contented cows that go and get milked when they want, sleep when they want and eat when they want,” said Hugh.

Teat health and somatic cell counts have also improved since the robots were introduced, a benefit Hugh said of the way cows are milked by a robot compared to in the parlour.

“A robot mimics the way a cow would be suckled naturally, so that if there is one quarter that has less milk in it than the other, it stops milking that quarter. Our SCC used to be 180-190 in the parlour, but they are regularly 100-110 milking through the robots.”

Cow comfort obviously adds to the improved yields and teat health, and with the herd housed in spacious cubicles with mayo mattresses and regularly scrapped slats, cows are kept clean.

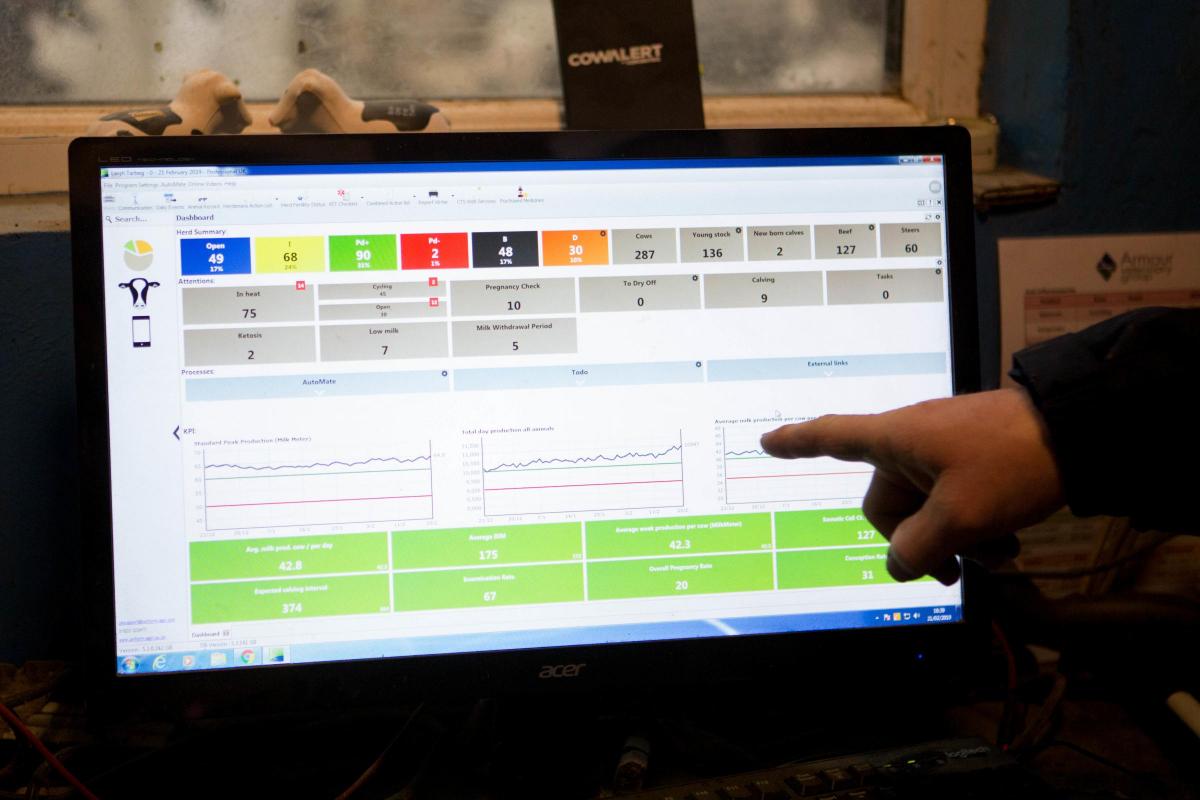

All females have Lely management collars which not only identifies the animal when it goes into the robot but also in to the out of robot feeders. And with the robot able to identify any abnormalities in the milk from individual animals and within individual quarters, health issues are picked up a good 12 hours before they would be normally, the Watsons said. The collars also measure activity, rumination and heat detection better than the human eye.

Depending on the stage of lactation, milking females can access the robot up to a maximum of five times during a 24-hour period during which they are either fed a 16% protein high energy blend specially devised by Davidsons Animal Feeds, if under 140 days in milk. After 140days, cows are given an 18% protein slightly lower energy feed in the robot. High yielders giving more than 45kg also get access to out of robot feeders.

All milkers are fed the same compact TMR comprising 7kg of the Davidsons 18% protein blend along with 0.3kg of C16 fat; 8kg of fodder beet (fed in the winter and spring months only) and 7kg of water which is steeped for two hours before adding 0.75kg of ground wheat straw and 26.5kg of top quality first cut silage per head per day.

It’s a feeding regime that does take longer to mix being steeped, but it is a process that the team believe has helped increase milk yields by 1.5kg per head per day as the cows are no longer able to ‘sort’ feeds.

Add to that the better quality silage produced over the past year, and the boys’ are confident this new type of feed has helped boost milk yields and fertility.

Alastair is also a firm believer in the benefits of fodder beet in the ration during the winter months as it has been shown to improve dry matter intakes, increase butterfat percentages and reduce the risk of stomach problems.

Investing in a Lely Juno silage pusher has helped to increase milk yields by a litre per cow per day too, according to Alastair.

It is nevertheless the purchase of a rotagrinder that has made one of the biggest differences to herd health and productivity over the past couple of years both in the milking and transition periods.

“The rotagrinder has made a massive difference to health and the productivity of the herd,” said Alastair who also does some contract work with the machine.

“It grinds the straw down to shorter lengths (0.5-0.75 of an inch) than a feed wagon, so cows can’t ‘sort’ feeds, therefore, the rumen is kept full with chopped straw which is particularly important during the dry period.

“We’ve calved less to zero cows that have had milk fever since we got the rotagrinder,” Alastair said.

The Watsons also give their fresh animals a propolene glycol energy boost for their first 60 days in milk to combat any negative energy balance.

While huge investment has been made over the years to improve overall levels of efficiency and production, it is an ongoing process as the vet, Alan Walker of Armour Vet Centre, Mauchline and Davidson’s nutritionist, John Rogers are regular visitors to the farm to monitor herd health and nutritional content of the feed. John also regularly analyses the quality of the forage to ensure the ration meets the nutritional requirements of the cows at any one time.

Foot trimmer David Murray is another regular visitor to the farm as all cows get their feed trimmed at 60 days in milk; 100 days and when they’re drying off. In addition, milkers all go through a mobile foot bath two days a week. It’s a costly process, but it’s one which pays dividends, as there has been no dermatitis on the farm for several years now.

As milk yields begin to dip from their peak levels, the number of times individuals can access the robot is reduced to such an extent that 10 days before drying off, individuals can only access the parlour once a day and receive no feeding.

Dried off 60 days pre-calving they are then split into two groups – far off calving and near calving, with the former fed a mixture of mostly chopped straw, water and a small amount of silage.

In the final three weeks of the transition period, up to 4kg of a Davidsons pre-calving cake is introduced to the same ration.

With all replacements bought as fresh heifers from 10-12 different herds in Scotland through Ayr mart, all cows are AI’d to Genus beef bulls of which the vast majority are Limousin. Calves are fed their mother’s colostrum for the first two days in individual pens and are then penned in groups and fed a 26%P Provimi milk replacer twice a day via a milk bar with straw and concentrates freely available from day one.

The team has also experimented with group hutches outside, which are proving a huge success, with less pneumonia compared to the calves housed inside in group pens.

With strong local demand for Limousin cross dairy calves, all the heifer calves and a good number of the bullock calves are easily sold at the door anything from two weeks to two months of age. Any that are left are sold as forward stores off grass through Craig Wilson, Ayr, as there is no space to finish them on farm.

The installation of the five Lely robots may appear an extremely costly option to milk cows but having been introduced in stages as the two herds came together, they have undoubtedly more than paid their way. Furthermore, they are still working – eight years on with few if any problems, making dairy farming a lot easier and more manageable for all concerned.

And while Hugh and Moira – who also runs a successful Bed and Breakfast business – and Alastair are still extremely busy attending to their ‘happy cows,’ they do at least now have the time to have farm visits from the general public, and more importantly, school children through the Royal Highland Education Trust.

After last year’s big win, they’ll have a lot more now too … Just check out the B and B and farm views at www.laightarbeg.co.uk

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here