Recently, the EuroTier extravaganza – one of the biggest livestock events in Europe – got underway and Chris McCullough trawled the 15 halls of exhibits at the German event to report on some of the latest and most relevant innovations for livestock farmers.

A whopping 155,000 visitors attended the event which is classed as the world’s leading trade fair for animal production, organised by the German Agricultural Society, DLG. This year, 2526 exhibitors from 62 countries exhibited modern animal production solutions across more than 260,000 square metres of space.

Whether it was new machinery or tweaks to existing models, latest software to help farmers manage their animals virtually, or new developments in feeding technology, EuroTier had it all.

If farming is to be sustainable in the future there is no doubt the industry needs to embrace new technology by the horns and put it into practice.

Some of the latest trends at the show included the most luxurious and expensive cow mat in the world, on-farm dairy pasteurisers, and of course lots of robotics.

However, not all farmers can afford the huge investments some technology requires in order to fully utilise it. And not all new technology makes it to commercial sales stage.

He writes that Scottish livestock farmers could learn a thing or two about livestock production at the biennial show. Here’s some of the highlights:

Home cheese production made easy

Producing home-made cheese is becoming popular across the world on dairy farms thanks to systems such as the new MP Cheese Pasteuriser from Greek company, Milkplan.

Made from easy cleaned stainless steel, the system is for use on farms that want to produce cheese and in smaller food processing companies.

Milk pasteurising and coagulation processes happen in the same tank thus saving equipment cost, space and user’s time. Both the agitation paddle and the cutters can also be removed for easier cleaning.

The system on display incorporated the main pasteuriser unit with a 200-litre capacity, a control panel and a cooling unit, together costing around €10,000 (£8900).

However, larger sizes of 300 litres to 1000 litres are available.

Automated feeder increases efficiency

Robotic feeding will one day become the norm in livestock sheds and the system developed by Austrian livestock equipment specialists, Wasserbauer, is ready.

The new system consists of the Shuttle Eco which acts as vehicle with a 2.2 cubic metre capacity for collecting the feed and distributing it to the cattle. Using the Nano feeding concept Wasserbauer has incorporated this unit with the new, unique lift for fully automatic feed removal in the bunker silo.

The feeding robot is battery powered and moves freely around the shed via magnets in the ground. As a result, it can easily be used in several sheds and can move to several silos.

The Shuttle Eco feeds animals around the clock, 365 days a year, with precisely tailored amounts of fresh food and the best part is, it will never ask for time off!

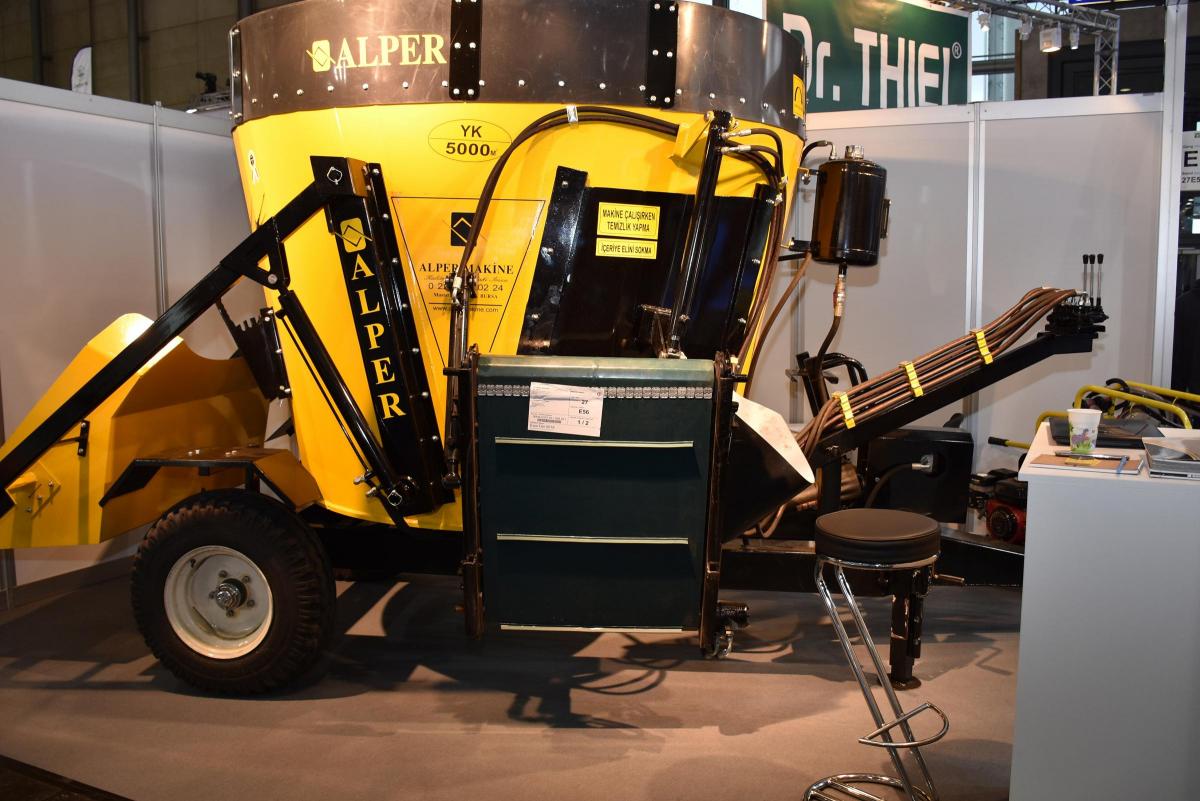

Turkish feeder feeds itself

Diet feeders of all shapes and sizes were present at EuroTier, including the new Alper YK5000 model which is made in Turkey and from a manufacturer already making strong headway in a number of machinery markets across the world by being competitive on price.

Capable of feeding 50 cattle, this five cubic metre capacity machine costs €6129 (£5450) plus shipping. Included in the price is the option of a left or right side dispenser, plus an onboard loading bucket for the ingredients.

It weighs 1900kg, has a load capacity of 1500kg, has five fixed cutting knives and can be driven by a 60hp tractor. Scales can be added to the unit to measure the exact amount of raw materials required for the ration. The latest model comes with an Italian made gearbox and an overall two year warranty on all parts.

First cluster to use a cartridge

Faster milk flows and improved teat conditions are just two of the benefits of the new DeLaval Evanza milking cluster and cartridge liner combination.

This new cluster is the first one in the world to use a cartridge liner which is simply replaced by twisting it open and again to close. DeLaval said farms that tested the new cluster system found increases in milk flow of up to 9%, higher yields of up to 5% and reduced milking time by up to 7%.

The new cluster can be used on any conventional milking system such as stanchion systems, parallel parlours, herringbone parlours, tandem parlours and rotaries. Made of rubber, the cartridges are completely recyclable.

Murska adds crimper

Finnish mill manufacturer, Murska, was looking for global dealers at EuroTier for its range of crimping machines in the W-Max range.

Everyone knows what the benefits of crimping grain are in terms of no drying costs and the improved feed quality, so Murska is expanding its fleet. The new W-Max 15 model has a capacity of up to 30 tonnes per hour of harvest moist grain which can be filled into tubes using a three to five metre discharge elevator connected to the mill.

With a 400-litre volume tank and a loading height of 2.91m, the W-Max 15 is designed for the medium to large scale farmer and contractors. Also in the W-Max range are machines with 10 and 20 tonnes per hour capacity.

World’s most expensive cow mattress

IF Carlsberg did cow mattresses, they probably would make something like the new luxurious example just launched by Cowhouse International, in The Netherlands.

The Dutch Mountain mattress is potentially the most expensive one in the world at a whopping €325 (£289) per cow, but the manufacturer claims it offers the best comfort to the animal.

Essentially, it is a unique piece of foam developed and manufactured by the company, which is 14cm thick at the front, sloping down to 10cm at the rear. Like the best mattresses, it is designed to adapt to the shape of the cow and follow all her movements. The foam is completely enveloped by a 1mm thick waterproof rubber membrane and is then covered by an 8mm thick polypropylene 3D topcover.

Cows lie comfortably for longer periods of time without pain resulting in higher health and more milk production, and intensive testing has already been carried out on this mattress which comes with a three-year warranty and it should last 10-15 years.

New milk feeder saves time

FEEDING high numbers of calves can be a real pain, but a new mobile unit that can feed up to 50 calves at once should help ease you through the stress.

German company, Patura, has introduced its mobile milk express unit developed especially for large herds wanting to feed a lot of calves. It can be transported all around the farm and placed either indoors in pens or outdoors in the fields.

The tank holds 500 litres of milk that is mixed within three to five minutes with the onboard Honda four-stroke pump. The unit on display at EuroTier had 30 teats and so could feed 30 calves, but this can be increased to 50 should the farmer require it. There is also a 5m dispensing nozzle at the rear of the feeder should the operator prefer to feed calves in single pens, dispensing the milk from the large tank.

A float level indicates the quantity of milk remaining inside the tank. A self-cleaning programme is used to completely clean the unit with clean water inside three minutes.

This complete unit with 30 teats costs in the region of €7000 (£6232).

Avant’s electric loader in production

Finnish wheeled-loader manufacturer, Avant, is now in full production of its new e6 all electric wheeled loader which has been showing strong customer support.

The new e6 is a sister model of the company’s already established e5 but powered by a lithium ion battery instead of the lead acid battery in the e5. By using this battery technology, the loader can operate in normal working conditions for up to five hours on a one hour charge time.

The e6 is designed for operators who need to use an electric loader continuously in emission sensitive areas and is priced around €45,000 (£40,000).

Jani Kakela, Avant Tecno’s vice-president as well as sales and marketing director, said: “Sales of the e6 are strong and we are in our fourth week of production now. We will be exporting it into most of our aligned countries with the US looking like early 2019 after sorting some approval issues.”

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereComments are closed on this article