INNOVATIVE thinking which has led to significant benefits for precision farming have won John Deere gold and silver medals, which will be presented at Agritechnica in November.

Its systems and ‘cloud-based’ data harvesting have won a gold medal and three silver medals by the DLG Innovations Commission. It was up against tough competition for the awards as there were more than 290 innovations in this year’s competition.

“John Deere invests more than 5% of its sales in research and development and these medals demonstrate our innovative strength,” said Dennis J Docherty, John Deere’s vice-president of sales and marketing. “We are particularly proud of our ongoing collaboration with industry partners and service providers.

“Partnering and system openness are the main success factors for the further digitalisation of the farm industry. Our company is developing innovative solutions that allow farmers and contractors to make more profit from their field operations.”

The gold was for its eAutoPowr transmission and intelligent e8WD system, which is the first electro-mechanical, split-path infinitely variable transmission. Its integrated generator delivers up to 100kW power for external applications and implement electrification and John Deere and specialist manufacturer, Joskin, have worked together to demonstrate a highly productive traction assist system solution for liquid manure application.

This has allowed a modified Joskin slurry tanker to have two drive axles leading to a significant increase in traction and less wheelslip.

The silvers went to:

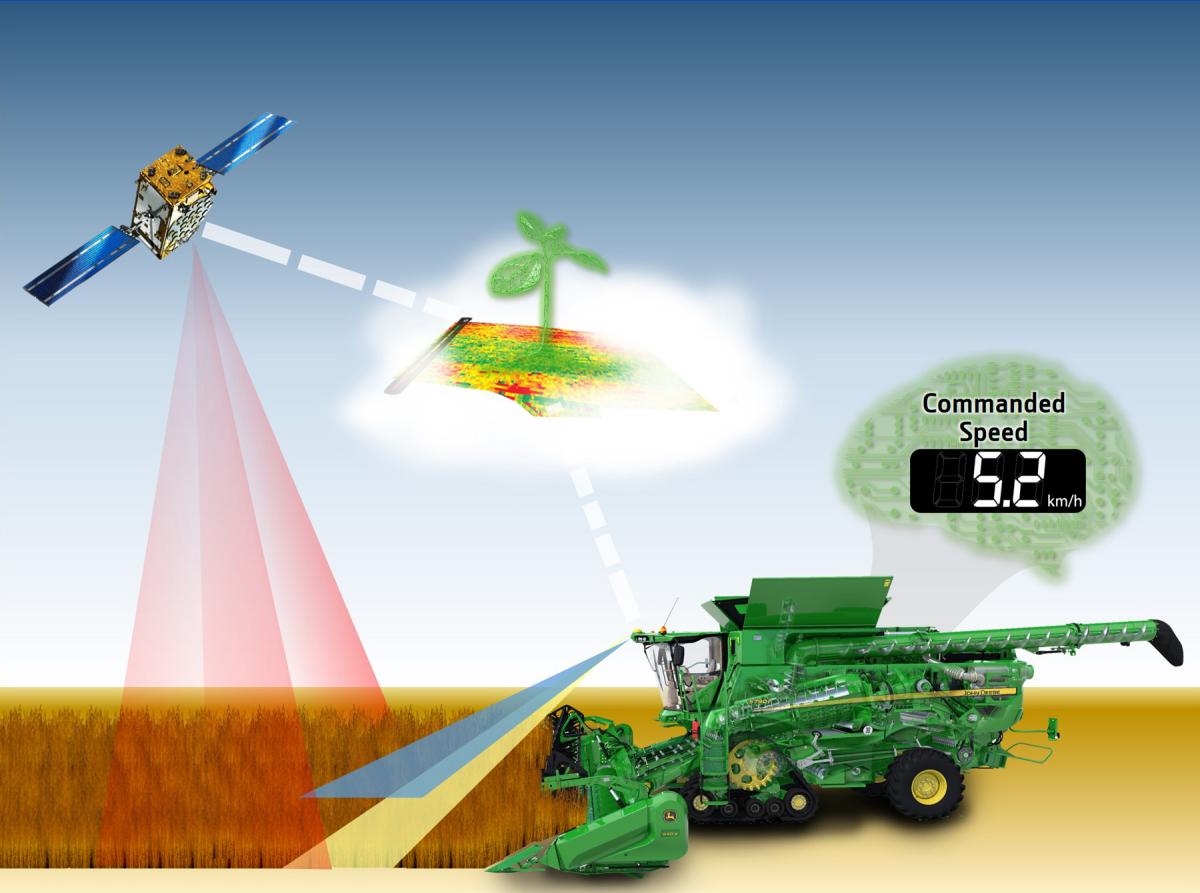

The Predictive Feedrate Control system in its combine harvesters, which combines two pro-active input sources from GPS satellites and cab mounted sensors.

This self-learning technology uses forward-looking perception information as well as crop data to allow the combine to react to changing harvest conditions and particularly to special situations such as a lodged crop.

To the new intelligent large square baler ride control for large square balers, where fluctuations in power and torque can cause significant tractor pitch vibrations, which puts considerable strain on the operator.

Using intelligent control of the transmission and a self-learning control algorithm, this active pitch dampening system almost entirely eliminates annoying movements.

JD’s large combine efficiency package optimises all critical functional areas of the combine to significantly enhance efficiency.

A lean drive concept, with innovative drive belts, makes this possible, while at the same time reducing power requirements. Further efficiency gains have been achieved in the engine, transmission, separation and ventilation systems and the straw chopper.

These efficiency improvements have led to a significant increase in harvesting capacity using the same engine power but with losses of less than 1%.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereComments are closed on this article