IT'S BEEN a talisman for harvesting excellence since it was first introduced in 1995 and now the Claas Lexion range of combines has undergone it's biggest redevelopment since then.

This 'second generation has been 10 years in development, with 1m hours of development time and and more than 6000 hours of endurance testing, the new Lexion APS Sunflow Hybrid range has been completely redesigned from the ground up.

About 66% of parts are completely different to current models, which account for around 75% of all hybrid and rotary combines sold in the UK.

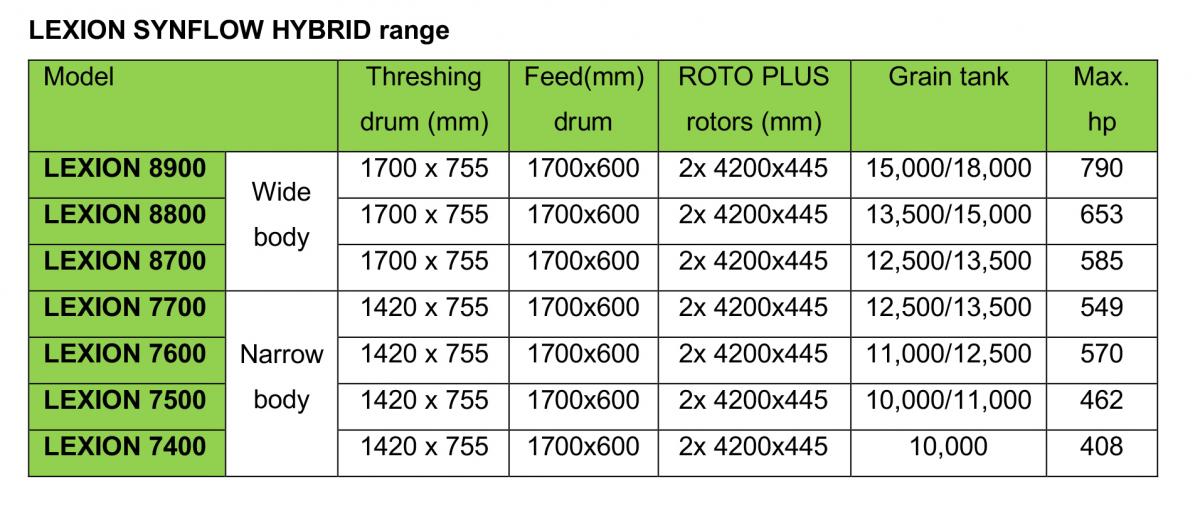

Two versions will be available. The new Lexion 8000 is a wide body machine that comprises of three models, including the new flagship 790hp 8900 model, making this the world’s most powerful production combine. It can be used with the latest 13.8m (45 ft) wide Vario cutterbar.

There will also be a further five models in the new narrow body Lexion 7000 range.

As part of the development programme, there were about 220 pre-series machines working across 10 countries worldwide – including in the UK – and Claas said these consistently demonstrated increases in output of around 10% compared on a like-for-like basis with current models.

The largest single factor in that has been the APS threshing system and its Synflow development. This is designed to thresh out 70% of grain, leaving 30% to be removed by the Roto Plus secondary separation system.

Central to that main system is a new 755mm diameter threshing drum – 26% larger than the current 600mm drum on the current Lexion 780 – and is fitted with 10 rasp bars, compared to eight. Alongside this is a new 600mm diameter feed drum (57% larger).

This greater diameter, plus potentially higher centrifugal speed of the rasp bars, has allowed the drum speed to be reduced to typically run at 550rpm, compared to 750rpm, for the same rasp bar velocity. Drum speed is infinitely variable using the Cebis control system from 330rpm to 930rpm, compared to a range of 450rpm to 1050rpm on the outgoing models and is fully synchronised with the accelerator and feed drums.

It also means that the separation area has been considerably increased. The 8000 models have a massive concave area of 1.55m2 and at 1.30m2 the concave area on the narrow body 7000 is even more than that on the current top-of-the-range 780 at 1.26m2.

Greater control over the threshing area comes from hydraulic operation of the main concave flaps, actuated from the cab and there is a new hydraulic pivoting concave bar between the pre-separation concave and main concave that can be engaged via Cebis for harder to thresh crops.

The new concave design makes it easier to change between crops and means that 40% of the main concave segments can be pulled out sideways and changed for different crops, such as beans. For ease of maintenance, the stone trap also now incorporates a self-cleaning mechanism.

The Roto Plus secondary system has better crop flow, plus changed angles on the rotors to reduce straw damage.

Grain tank capacity has been increased up to 18,000 litres on the new 8900 and on top of that the tank access has been improved. Maximum unloading speed is 180 litres/second with full clearance in just 100 seconds.

There's also a new, larger cab with better sound proofing and a new grain tank window – and taller operators will welcome the fact that the seat can be moved further back for greater legroom.

All main functions are in Cmotion control allied to the latest Cebis touchscreen terminal, which can be adjusted independent of the armrest or even swung out of the way for improved visibility.

There are three different ways of adjusting the main settings – using either the Cebis touchscreen, the rotary push switch on the Cebis control panel, or via direct switches on the new Lexion armrest. This armrest is fully adjustable for reach and height and also includes radio and telephone controls and a USB charger socket.

Both Lexion ranges are powered by either MAN or Mercedes-Benz engines, with power outputs ranging from 408hp on the smallest Lexion 7400 to a new high of 790hp for the flagship 8900.

All are fitted with and intelligent engine management system which automatically adjusts engine power output relative to load, with variable fan cooling also standard on all models.

This new drive system has been proven in Jaguar forage harvesters and gives a more positive, smooth engagement of the threshing and auger systems. A new clutch system engages and tensions the belts. A straight line design of the drive results in lower power loss and has reduced the number of belts.

As usual, they can comes with wheels or the Terra Trac track system but both are capable of travelling at 40kph. All wheeled machines are now available with a differential lock and larger tyre sizes can also be specified for both the front and back.

Unlike the volumetric yield measuring system used in the current Lexion, the new Quantimeter yield measuring system fitted to all models, takes its information from a pressure cell. Not only is this far more accurate and robust, but it only needs to be calibrated once a year for each crop type.

Originally launched in 1999, the Laserpilot automatic steering system is fitted – more than 70% of all Lexions sold in the UK feature some form of steering system – but for the new ranges. there's waht Claas is calling Field Scanner automatic steering. This uses a radar scanner originally developed by Audi, which is mounted on the top of the cab and can scan over an arc of 145 degrees to both the left and the right. It is capable of recognising both standing crops higher than 10cm and tramlines, requires no calibration, is easy to set-up and because it can follow tramlines is suitable for use within a reduced traffic system.

New engines for Avero combines

Claas' Avero combines have a new engine to comply with the Stage V emission standard, but which also ups power.

The 6.7-litre Cummins B6.7 develops 213 hp, which is 8 hp more than the current model. Compliance with the Stage V emission standard is achieved by means of SCR and DPF technology, with a urea tank capacity of 49 litres and without the need for exhaust gas recirculation.

This after-treatment system takes up significantly less space and means there is greater accessibility for maintenance.

The Avero 240 also gets the APS threshing system, which gives is up to 20% greater throughput for the same fuel consumption than the standard spec'..

Residual grain separation is done by four straw walkers with four steps. Using agitator tines, the intensive separation system is able to handle even large volumes of straw and ensures maximum separation of the residual grains.

The grain tank volume is now 5600 litres, with an unloading time is less than two minutes.

New draper cutterbar

A new range of draper type cutterbars for use with the 2020 season Lexions have been designed, while a wider 13.8m wide version of the Vario cutterbar will also be available.

The Convio cutterbar is available in five working widths from 7.7m up to 13.8m, with two models available – the standard version has a rigid cutterbar, while the Convio Flex has a flexible cutterbar for crops close to the ground, such as peas and herbage seed.

With the Flex headers, the side belts are flexible, with the knife bar moving over a range of 225mm, from 90mm upwards and 135mm downwards.

Both cutterbars use the well proven Auto Contour system, while Active Float allows the operator to alter the ground pressure of the cutterbar depending on ground conditions.

They also have a new design of reel with an adjustable cam track that if necessary allows the reel to be set so that it picks the crop up ahead of the knife bar, for instance in laid crops.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here