A SCOTTISH trailer manufacturer provided one of the ‘surprise’ highlights of this year’s LAMMA show, with a new, on-the-go central tyre inflation system for its twin and tri-axle grain trailers.

James Stewart, of Stewart Trailers, Aberdeenshire, said he had a serious amount of enquiries about the new system which aims to make full use of new tyre technology that can offer reduced in-field tyre pressures to help reduce soil compaction, which has become a major issue on some farms.

The problem is, that this requires the tyres to be deflated and re-inflated each time the tractor and trailer combination moves from road to field, or vice-versa. Mr Stewart said this new system – which adds from £5000 to the cost of a new trailer – will allow drivers to do this from the tractor cab.

Given the wet harvest season, it’s little surprise that this new option for the popular blue trailer range has had such an interest. “Soil compaction issues have really been brought home by weather conditions and the fact is that a lot of tyre manufacturers now supply ideal tyre technology which can help reduce it,” he told The Scottish Farmer.

“This central tyre inflation system aims to make it easier for operators to the most of that technology by allowing them to quickly change from a ‘road mode’ to field operation at the press of a button,” said Mr Stewart, whose business makes a variety of trailer types at its base near Inverurie.

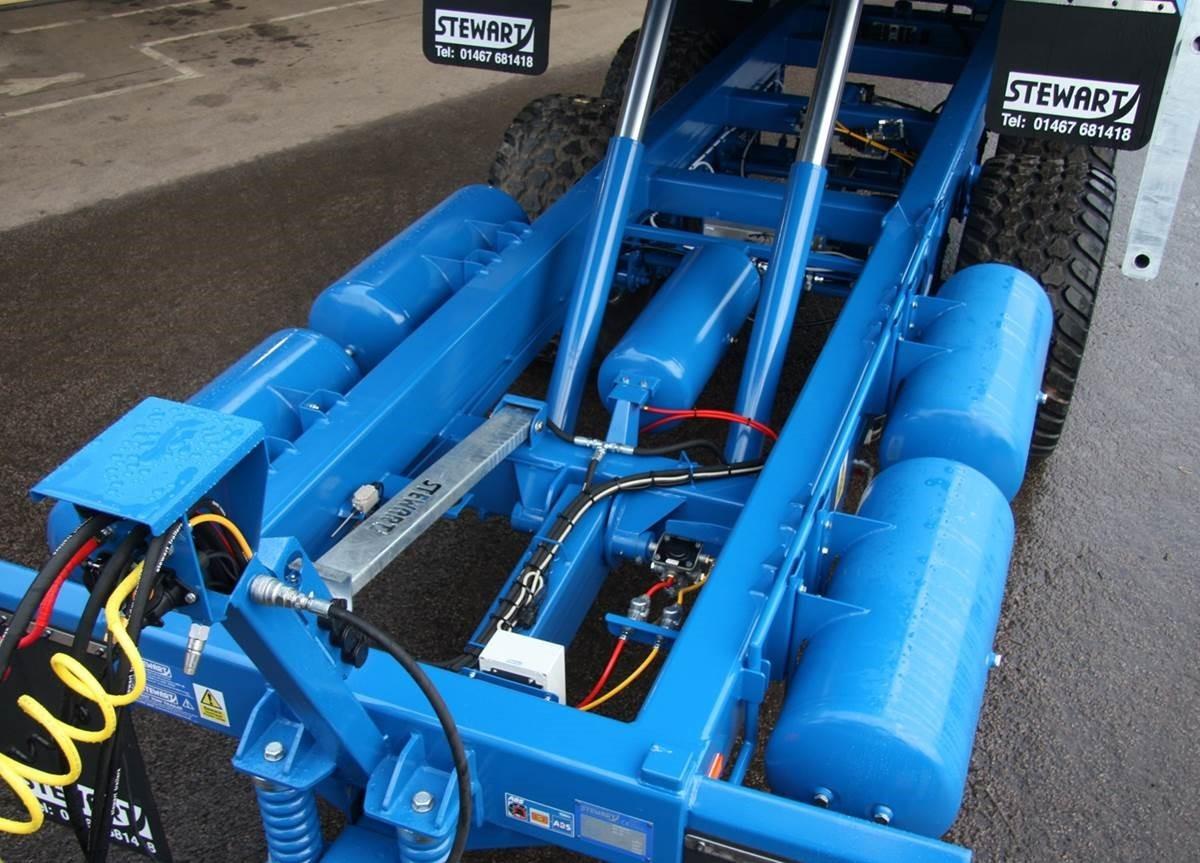

From the tractor cab, operators can deflate low ground pressure tyres down to 1.5 bar when they go into a field to give a much increased tyre footprint and then re-inflate them to a working 5 bar pressure when heading for the road, for secure and safe high-speed transit.

Each operation takes about 45 seconds and a fail-safe is built into the system so that if an operator leaves the field without first re-inflating the tyres, a speed sensor automatically kicks in the compressor to take them up to a pre-set pressure, should they forget.

This system is mainly aimed for use in the company’s grain trailer range, which Stewart makes from 13 to 24 tonnes and in twin and tri-axle configurations. The twin-axle variants will most likely work off the tractor’s compressor, said Mr Stewart, while the extra demands of a tri-axle set-up requires a compressor on the trailer itself.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here