During the last 10 years, the McHale V6 range has become the machine of choice for making bales from 0.6m-1.68m – and now it;s been made even better.

McHale has listened to its customer base across the UK, Australia, America, France and Poland, to produce a variable chamber baler that can output a larger diameter bale.

Over the last three years, it has worked to both design and test what will now be its largest variable chamber baler, the V8, which can produce a bale up to 1.9m in diameter.

This meant the introduction of the McHale V8940 non-chopper baler and the McHale V8950 15-knife chopper baler. These high output machines can produce dense bales from 0.6m-1.9m in diameter. This increase in bale size and increased density means the V8 baler can produce bales with up to 30% more crop in a 1.9m bale than that achieved in a 1.68m V6 bale.

The new balers have a higher intake capacity, mainly thanks to a new pick-up, with a choice of cam track or cam-less.

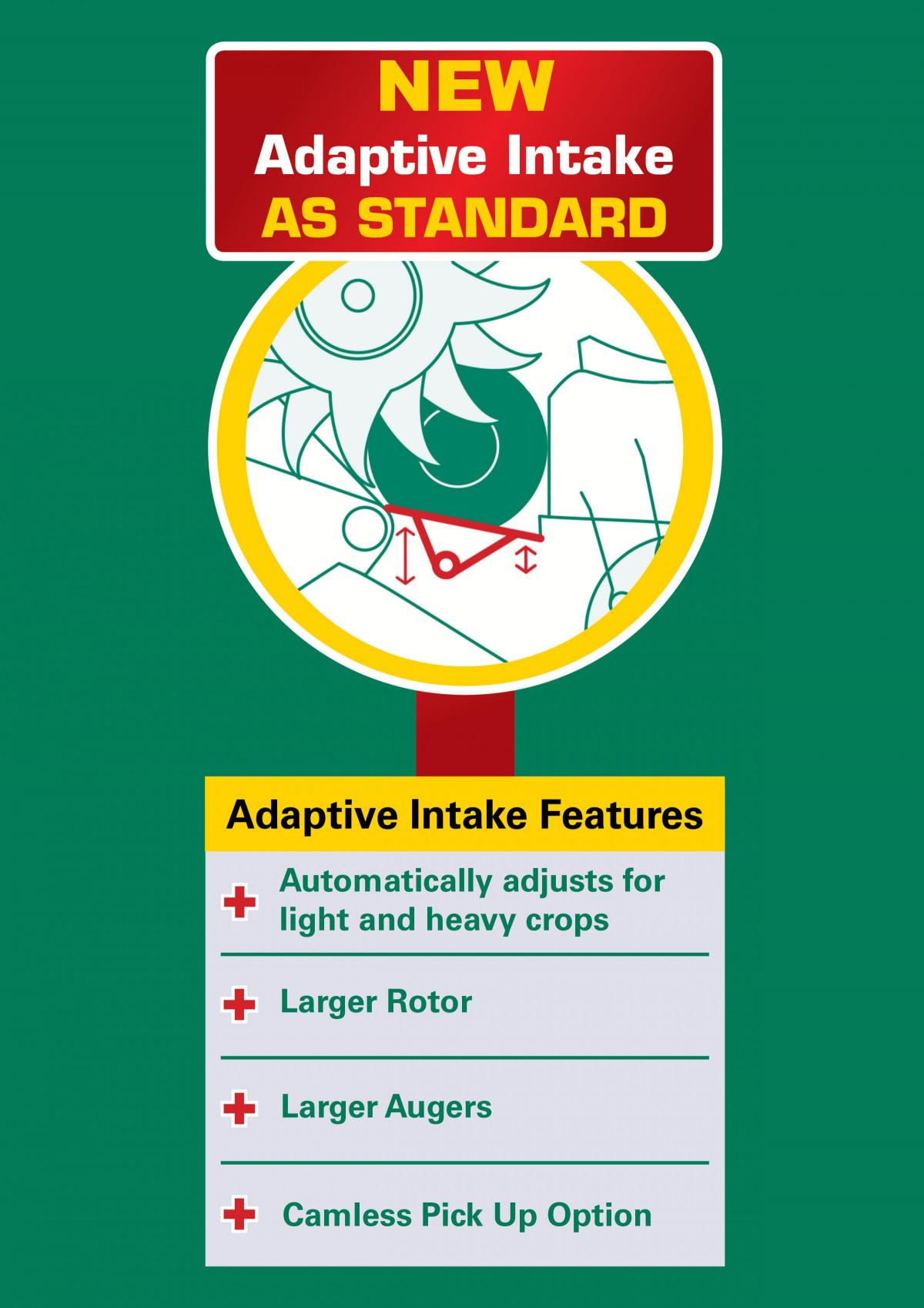

Then, the bigger lateral feed augers and rotor, plus adaptive intake push the crop through the system towards the feed chamber, via the selectable knives set-up if that's the version chosen

As usual there are many heavy-duty components built in to the machine allowing it to handle the toughest of crops and ground conditions.

Martin McHale, the marketing and sales director said: “These new V8 balers have expanded our variable chamber baler range, which is recognised worldwide for making well-shaped, high density bales.

The V8940 and V8950 have brought baling to a new level with higher density, increased bale size, better intake and easier maintenance.”

The new pick-up can either come with a five-tine bar cam track pick-up, or as a six-tine bar cam-less option, with double crop roller. McHale has also increased the size of the lateral feed augers which direct crop into the rotor, while also increasing the rotor diameter to improve throughput.

The angle at which the floor is positioned has also been redesigned to maximise the flow of crop into the chamber.

The new adaptive intake has been designed to allow the intake area to automatically adjust to changes in material flow.

This means there's less chance of blockages occurring as the floor automatically adjusts to allow the machine to better handle uneven rows / swaths

The 15-knife chopper unit on the McHale V8950, when fully engaged gives a theoretical chop length of approximately 65mm, but knives can be engaged and disengaged from the tractor cab. The optional selectable knife system consists of two knife banks that allow various configurations to be chosen to allow 0, 7, 8, or all 15 in work.

Also keeping blockages to a minimum is the drop floor unblocking system. Should one occur, the sound of the slip clutch alerts the operator, who then hydraulically lowers the floor from the tractor cab.

This widens the feed channel and on re-engaging the pto, the blockage can be fed through. The floor is then be reset so that baling can resume.

Both V8 balers come with three heavy-duty endless belts, which are reinforced with synthetic material to allow them to absorb and apply high pressure to material in the bale chamber. Bale size on both machines can be adjusted up from the minimum setting in increments of 10mm.

They are also fitted with a primary drive to aid belt and material rotation. On the McHale V8950, a secondary drive is fitted so that, in difficult conditions, should the primary drive slip, the secondary drive engages to ensure the material rotates in the chamber.

The high-performance netter features endless net adjustment, with capacity to take rolls of net up to 1310mm in width and 180° wrap around on the feed roller to prevent any net slippage while feeding.

The operator can adjust net tension on the control console from the tractor cab.

Manual greasing blocks are standard on the McHale V8940 and V8950 models, with the latter having the option of an automatic system.

Visually, there's a new look to the range, with twin skin durable panels that open upwards to provide better access to the machine’s components.

The Expert Plus control console, with its a large graphic display, means the operator can adjust most things from the tractor cab, including the selection of a soft or hard bale core.

A new bale shape indicator provides a more accurate reading of bale shape, feeding live information to the driver via the control console, regarding which side of the chamber to fill in order to get the best bale shape.

For the end game, there's a heavy-duty telescoping channel type bale kicker with a bale discharge sensor notifying the driver when the bale has left the chamber and passed over the kicker.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here