Ahead of the 2021 season, machinery giant, McHale, have made a number of updates across their wide range of balers following feedback from customers and extensive testing in Ireland and around the world.

Baler Range

Across their baler range, McHale are offering customers a choice of two pick-up options; a five-tine bar cam track pick-up or a six-tine bar camless pick-up. McHale have further developed their pick-ups with the introduction of larger augers to provide more efficient crop movement. The larger rotors direct crop into the rotor while the rotor has also increased in diameter to improve intake. The angle at which the floor is positioned has also been redesigned to maximise the flow of crop into the chamber.

This also includes the introduction of the adaptive intake which allows the intake area to automatically adjust for light and heavy crops to facilitate a smooth crop flow into the chamber. The adaptive intake plate sits higher in low volumes of crop and can adjust to a lower position for higher volumes of crop. This avoids peak loads and results in higher daily throughput regardless of working conditions.

New for the 2021 season, McHale have expanded their range of variable chamber balers with the introduction of the McHale V8940 non-chopper baler and the McHale V8950 15-knife chopper baler. These high output machines are designed to produce dense bales from 2’ – 6’ 3” in diameter. This increase in bale size and improved density means the McHale V8 baler can produce bales with up to 30% more crop in a 6’ 3” bale then what is achievable in a 5’ 6” V6 bale.

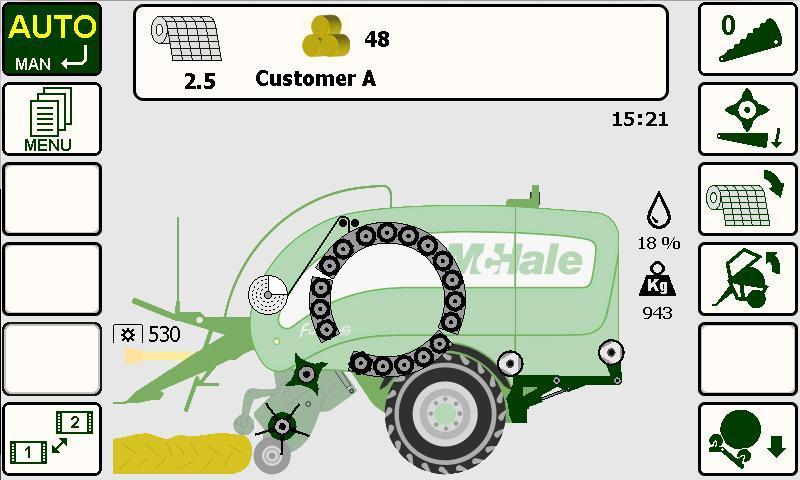

Also breing introduced this year is the McHale Fusion 3 Pro, which will get to work across the country. This machine expands the Fusion range and provides operators with a number of unique features such as: iTouch control console with 7” touch screen display; in-cab net adjustment; in-cab density adjustment; camera to show bale transfer and start of the wrapping process; auto drop floor reset; auto knife drop feature; bale tip speed adjustment; roll back wrapping feature to seal the bale after wrapping.

The Fusion 3 Pro also has the ability to add a number of optional extras which aren’t available on the standard McHale Fusion 3. As the Fusion 3 Pro is fitted with the iTouch Control Console, for people that want to monitor their baling process more, a moisture reading, bale weighing, and printer unit can be fitted to the machine. This allows the operator to record bale weight, dry matter content and other machine settings such as chopped or non-chopped, number of layers of wrapping film being applied, time spent baling and number of bales produced.

If all three options are fitted, the operator can print the final receipt at the end of the field giving bale total, average bale weight and average bale moisture content to the customer.

Bale Weighing Function

All new McHale Fusion 3 Plus machines can be fitted with an optional bale weighing functionality. As the bale is being tipped, the bale weight is recorded before gently placing the wrapped bale on the ground. This information can be provided to the customer who can visibly see the average bale weight of their produce.

Bale Moisture Sensor

A Bale Moisture Sensor can be fitted as an option on all new McHale Fusion 3 Pro and 3 Plus machines. This sensor is positioned in the side wall of the bale chamber and once the PTO speed is above 400rpm, a live crop moisture value is displayed on the screen throughout the baling process.

An average moisture content reading of the bale will then be displayed in blue on the iTouch control console. This average value is then accumulated in the on-screen customer profile and on the job print out receipt.

Printer

A receipt printer can be fitted to all iTouch control consoles on new McHale Fusion 3 Pro and 3 Plus machines as an optional extra. This allows the operator to print a detailed receipt outlining the work completed for a specific customer.

The receipt includes the following information which is also displayed in the customer profile on screen: contractors name and contact details; total bale count; total baling time; netting system: net/net replacement fill; wrapping system (on/off); knives (on/off); average moisture content ; average bale weight.

ISOBUS

ISOBUS is also available as an optional extra on all McHale Fusion 3 Pro and Fusion 3 Plus machines. When the machine is fitted with ISOBUS, it can be plugged into any ISOBUS tractor connection and operated through the terminal in the cab and, if required, the machine can also be specified with an optional ISOBUS terminal.

Focusing on the other machines in the McHale baler range of integrated baler wrappers, there are a number of points for improved operator comfort such at the Net Loading Device which aids operators position rolls of film or net on the platform. Additionally, customers have the ability to specify a 1000rpm gearbox on their McHale Fusion or baler and a spoon hitch is also available as an option if required.

For more information please contact your local McHale dealer.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here