CONSTANT wear and tear is par for the course when designing new cultivation equipment, but now specialist manufacturer, Väderstad, has taken this to a new level.

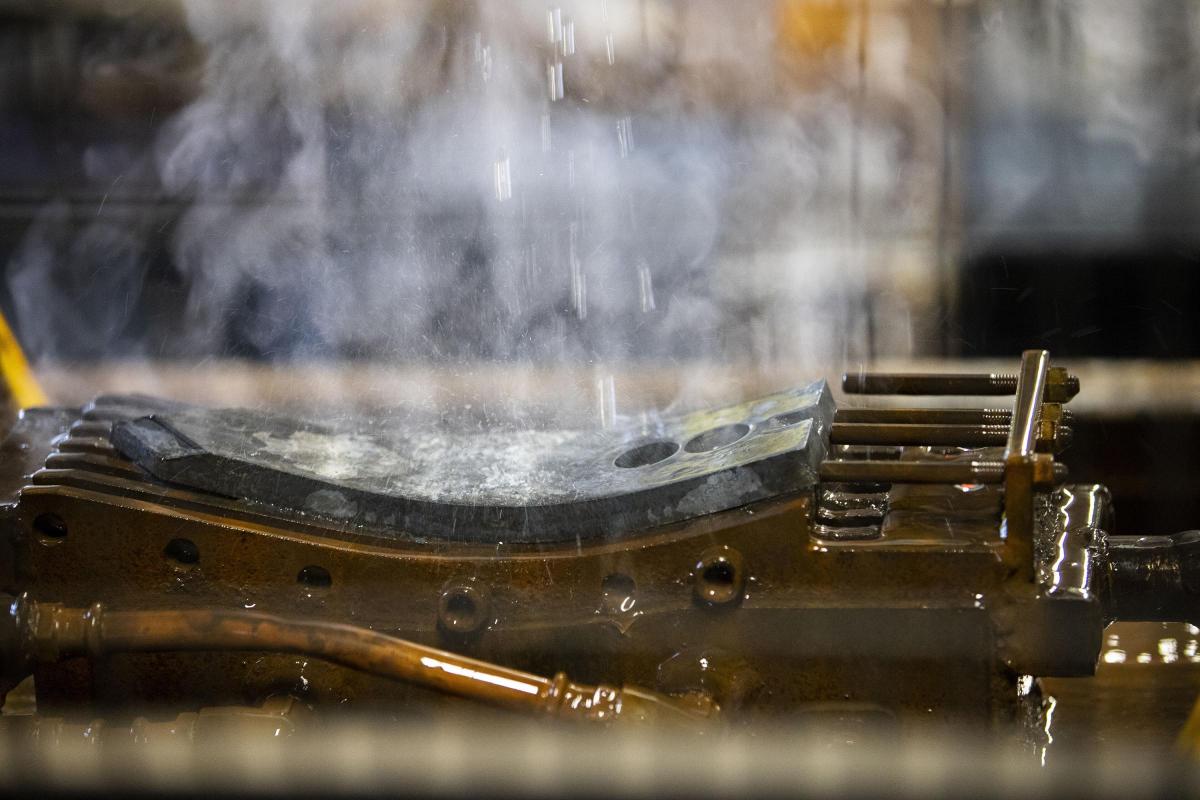

It has opened a new high technology material lab for producing wearing parts for its agricultural machinery range at its facility in Överum, Sweden.

The new facility will operate alongside the company’s existing components' factory that currently employees 50 skilled personnel and 40 robots. As a result of this investment, Väderstad will be able to perform unique tests in search of the best mechanical properties of materials used in making its own wear parts.

The new lab will be run by metallurgist and materials scientist, Anders Petersson, who explained that wearing parts must be made of a hardness that is also durable.

“If it’s too hard it becomes easily brittle and can crack when used in our machines,” he said. “It’s a balance between hardness and elasticity. Since Väderstad’s products are used all over the world, we also have to take into account the composition of the soils that differ around the world and produce a wear part in a material that works as well as possible in different conditions.” CEO of Väderstad components, Dan Smolin, added: “We are very proud of this investment. To have a development laboratory alongside our production in Överum will in the long run generate even better production, which in turn will create growth and new jobs.”

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereComments are closed on this article