Farmers have always been at the forefront of technology – from the horse being replaced by the tractor through to the sickle and the scythe giving way to the combine harvester.

That willingness to adopt inventions that can save time and save money have led to our farms being among the first places to embrace change. After all, the British agricultural revolution and the industrial revolution went hand-in-hand.

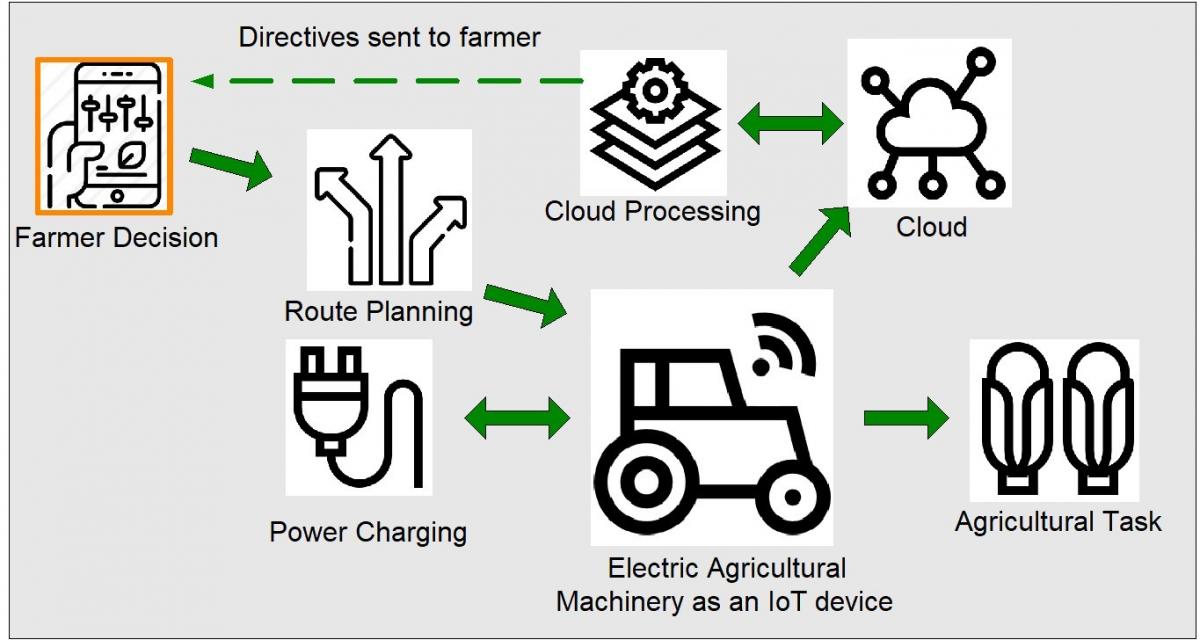

Now, with the emergence of the fourth industrial revolution – or 'Industry 4.0' to its friends – it’s digital technology that’s leading the way, in the form of data, robots, and sensors. Putting mobile phone chips inside sensors means that they can connect to the world wide web, creating an 'internet of things', or IoT for short.

The knowledge, the skills, and the technology are already out there – but how do we take the next step and move those innovations from the laboratory to the farm? How do we convince farmers of the merits of adopting this technology?

For me, it starts with a conversation. Sitting round a table, not as a farmer and a scientist or engineer, but just as two people who are focused on solving a problem.

I’ve been working in this field for more than 10 years and when I first started out, I wanted to talk and talk and talk, and share my enthusiasm about robotics. Now that I’ve got a few more grey hairs, I’ve learnt that it’s more important for me to listen than to talk.

That’s because I want to hear the problem that the farmer is trying to solve. It’s all very well us academics coming up with ideas, but what’s much more important is listening to what the problem actually is out there in the real world, and then working in partnership to solve it.

And that’s why we’re always keen to speak to farmers or to read their e-mails. Plus, when the National Robotarium, in Edinburgh, moves into its new building in October, we’ll be able to welcome farmers to come and see our robots and sensors, which will help to deepen those relationships and partnerships.

Next, collaboration is key. It’s really important to be able to speak the same language – about the farm, about business, and about solutions to problems. Sometimes those solutions won’t even involve a robot.

One of the farms on which I worked as a consultant grew oranges on the slopes of the Andes mountains, in Chile. The farmer contacted me and explained that they were having trouble getting their oranges down from the trees into the farm and they thought a robot would be the solution.

I visited the farm and looked at the problem, and we decided together that a better – and cheaper – solution was to use gravity instead of robots. We built small channels down the hillside, so gravity would take the oranges down, without the need for machines.

It was a great example of our three-stage process of listening to a problem, analysing that problem, and then finding common ground for the solution – plus, not going in with preconceived ideas.

Those collaborations can lead to great rewards for farmers. Another of my clients grew cherries and would count the shucks to predict how many cherries they expected to harvest, based on historical data.

The problem with the technique was that the error – or the uncertainty in the result – was as high as 30%. If the harvest was 30% below the estimate, then the farmer was spending too much money hiring workers and equipment that wasn’t needed; but if the harvest was 30% higher than the prediction, then not all the fruit could be brought in from the trees, leading to waste and lost sales.

The solution needed to be simple – and all the farmer needed to do was to record a video of the cherry trees on their mobile phone. They then uploaded the video to a computer server, where my software could automatically compare the video to data I’d gathered from apple, lemon, and orange farms in California and Spain.

Read more: Farmers confess to being nervous of new agri-tech

Within just a few seconds, the program could use its historical data to predict how many cherries would be harvested from the trees. Speed was important, but so was accuracy – it cut the uncertainty from 30% to just 8%.

That solution used artificial intelligence – what we humans call learning by example. It’s one of a number of machine-learning techniques that we scientists and engineers can use to make our robots and sensors more helpful to farmers.

The cherry farmer didn’t care about what was going on behind the scenes, though, and nor should he. We’re not trying to turn farmers into data scientists – instead, we’re trying to come up with solutions that are simple to use, like taking a video on a mobile phone and then getting the answer that’s needed quickly and accurately.

My job is to help pick the most suitable sensors and the most suitable platform, whether that be a robot or a drone, or something simpler, like attaching sensors to a tractor, or using a mobile phone. That then frees up the farmer to make their decisions, based on the most accurate data.

Sometimes it can take a while. I began working with an avocado farmer in 2014 and it took three years to start getting results. Avocado trees are ugly – not like our pretty apple trees in Scotland – with the fruit growing up in the treetops, but inside the canopy, not at the easy-to-reach edges.

Those three years didn’t go to waste, though. All the data we collected was fed into the deep-learning system, so it could make accurate predictions about harvests – again, with less than 10% uncertainty.

Handling those huge amounts of data about harvest predictions and yield mapping isn’t something farmers should need to worry about either. I use cloud storage, like Amazon Web Services, or any other – which just means the data is kept on a network of remote servers, instead of on a single computer – to process the data, so that farmer just gets the information they need to make their decision.

Using robots and data won’t be for everyone – just like electric cars won’t be for everyone. The outgoing generation of farmers is likely to shun digital technology, just like our parents’ generation is likely to shun electric cars.

Yet, for our generation – and our children’s generation – using data, robots, and sensors will become normal, just like electric cars will become normal.

About the author:

Dr Fernando Auat Cheein is Associate Professor in Robotics and Autonomous Systems at the National Robotarium at Heriot-Watt University. He has published more than 100 journal articles, several conference papers and been granted several patents. The author of two books and editor of two more, he is also associate editor of Computers in Electronics in Agriculture and Biosystems Engineering (both Q1 journals in the field), among others.

About the National Robotarium:

The National Robotarium is a partnership between Heriot-Watt University and the University of Edinburgh which combines Heriot-Watt’s engineering heritage and strengths in robotics for hazardous environments, manufacturing, healthcare, and human-robot interaction with the University of Edinburgh’s expertise in space, construction, and humanoid robotics. Funded by the Edinburgh and South East Scotland City Region Deal, the National Robotarium supports the Deal’s overarching objective of accelerating growth by attracting inward investment and talent. The National Robotarium building will open later this year on Heriot-Watt’s Edinburgh campus in 2022.

By Dr Fernando Auat Cheein, Associate Professor in Robotics and Autonomous Systems at the National Robotarium

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here