Cost-effective fertiliser or logistical nightmare? Slurry is a big concern for any farm.

Whether looking to increase herd size or simply maintain productivity, slurry storage is a significant investment and slurry management can be an tricky task.

Increasingly tough new environmental targets aim to reduce harmful emissions, especially those from agriculture. Whilst covering slurry is a seemingly rudimentary task, there are several factors to consider before making an investment.

Mike Kitching, a slurry storage specialist at Tramspread, offers some advice.

“Slurry management is a more holistic task than simply storage and application. The type of storage, how often and thoroughly the slurry is agitated, and whether any separation devices are used, will make a significant difference to the quality and quantity of the slurry,” said Mr Kitching.

Covering slurry can be costly because of the size, shape and location of the tank or lagoon. Creating new storage may require planning permission and greater capital outlay.

“If herd size is a constant then maintenance is a good way to make the most of existing storage. Agitating slurry regularly to prevent solid build up, and covering slurry to keep out rainwater, will enable accurate calculations to be made to ensure sufficient storage for the number of cows,” he explained.

The volume of a tank should be calculated based on benchmarked values per animal, the herd size and the land available to distribute the slurry to.

In nitrate vulnerable zones (NVZs), it is also important to account for additional rules that may prevent spreading at certain times.

“Allowing for growth is one consideration, but if a floating tile cover is being used the volume of the tank will increase with rainwater too. Canvas, or other rigid covers that block rainwater will prevent the slurry from being diluted and also reserve the full volume of the store for slurry.

Bag tanks are increasingly being used as a secure storage for excess slurry

"However, the store must have the structural integrity to bear the weight of the cover and it is important to mix the slurry to prevent a build-up of solids,” added Mr Kitching.

For a growing herd, there may be the need to look at new storage options to expand the slurry provision available. “Covering large lagoons can be costly and keeping slurry agitated to prevent solids building up is tricky with large square shaped lagoons because even the largest mixers will not be able to reach the middle of the lagoon,” he pointed out.

The cost and quality of materials for lagoon construction varies significantly and the concrete must be installed correctly to prevent slurry seeping into the ground.

Whilst concrete is a popular option, the environmental effects of slurry lagoons and stores that have failed are significant, especially if the store is large.

Detrimental effects to soil and ground water should be considered and above ground tanks offer a much better opportunity to monitor and maintain the integrity of a tank to prevent any leaks.

“A below ground slurry lagoon will require the retaining walls to support the external ground as well as the slurry inside the store. Above ground slurry storage offers options to safely maximise storage volume for farms with limited space,” explained Mr Kitching.

Stainless steel tanks may require planning permission and are a higher cost solution. Covering existing steel tanks can also be costly. However, there are floating covers available at a lower cost.

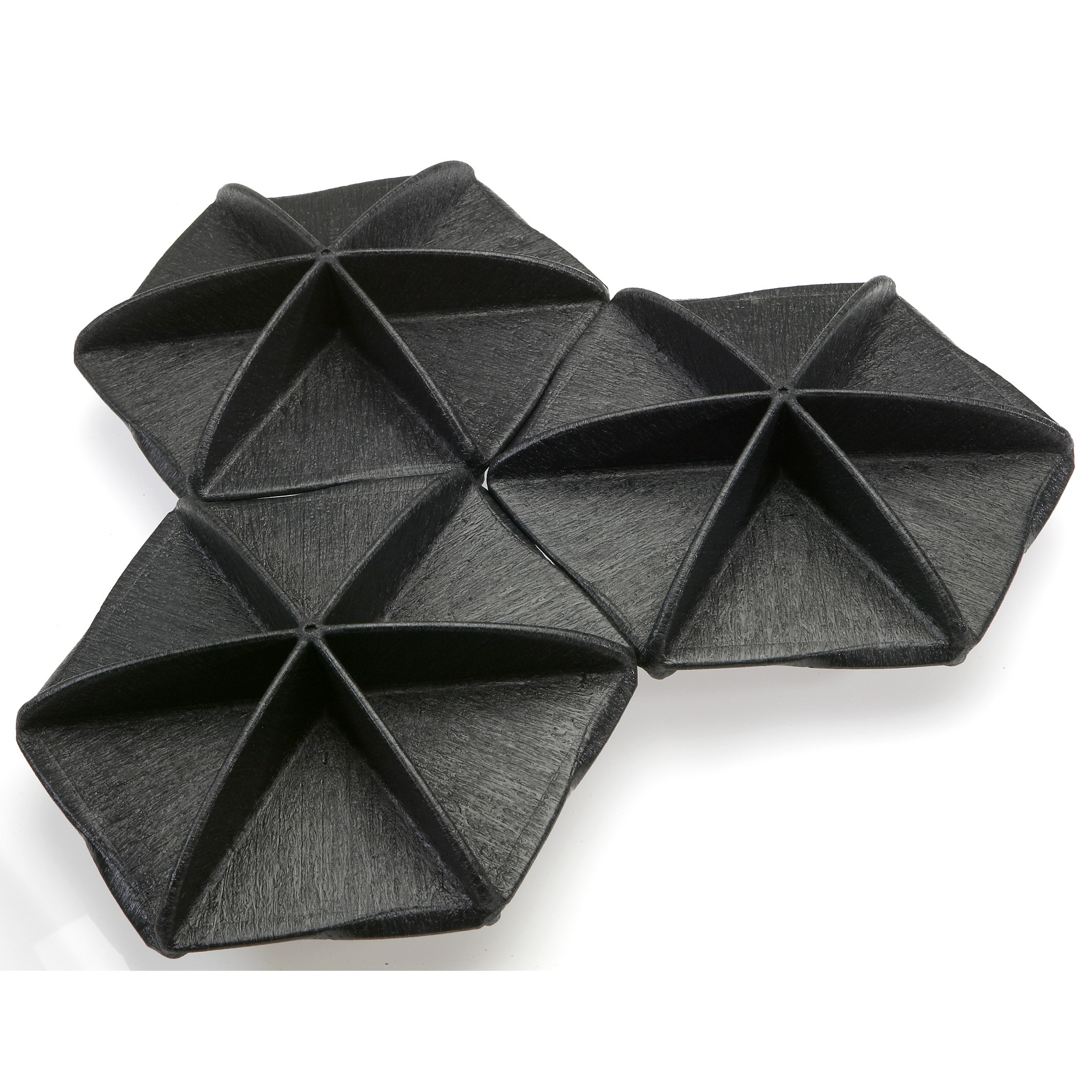

“Hexacover is a versatile product. It floats on the surface of the slurry to prevent 95% of emissions escaping and is approximately a quarter of the cost of a tensioned cover. However, it does not keep rainwater out so would be unsuitable for areas with heavy rainfall or farms close to their storage limit.”

Made of recycled polypropylene, these hexagonal tiles float on top of any liquid and fit together to fill any size space. The tiles block light out and gas in, whilst also helping to prevent a crust forming.

Using Hexa-Covers in slurry stores is a cheap option to retain emissions within the store, but won't keep out rain

“Crucially for busy farms, it requires no maintenance and can be installed in two to three hours. For farms with an existing steel tank, canvas covers can cost up to £30,000 for a 20m-diameter tank, whereas a floating solution for the same area would cost approximately £8000. It is also popular to cover lagoons because mixers can be inserted easily.”

Bag tanks range in size from 200 cubic metres to 7000 cubic metres and can be located on any soil type as only a shallow foundation is needed. Integral hydraulic, or electric stirrers enable easy and consistent agitation of slurry. The tanks are self-venting so relatively little management or farmer involvement is needed.

Bag tanks are manufactured in a UV-resistant, grey coloured material and, when installed, are low to the ground and have minimal impact on the surrounding landscape.

“Many farmers have installed Albers Alligator bag tanks without requiring planning permission. However, those looking to install a bag tank are advised to seek guidance from their local authority as the location of an installation may require approval,” advised Mr Kitching.

All slurry should be regularly agitated to prevent the build-up of solids which make it more difficult to pump and reduces the overall capacity of the store.

A variety of pto and electric agitators are available, but the type of storage will be a big determining factor when choosing.

“Electric agitators often have timers, so can be set to come on automatically. This is fine for storage close to or beneath buildings, but less easy for lagoons," he said.

"A good method is to mix the slurry in the reception pit, or channels before it is sent to the store. Reck produce a range of channel mixers that mix slurry before either separating or pumping directly to a store,” said Mr Kitching.

Tractor mounted mixers are popular to reach into lagoons and over high tanks. “For those with large lagoons, the Reck Typhoon mixer can be mounted on a frame to offer a 16m-long mixer. The Mammoth Titan can reach over a 5.9m tank. However, these options represent higher investments that may not be needed if a farmer were to use a separator,” he said.

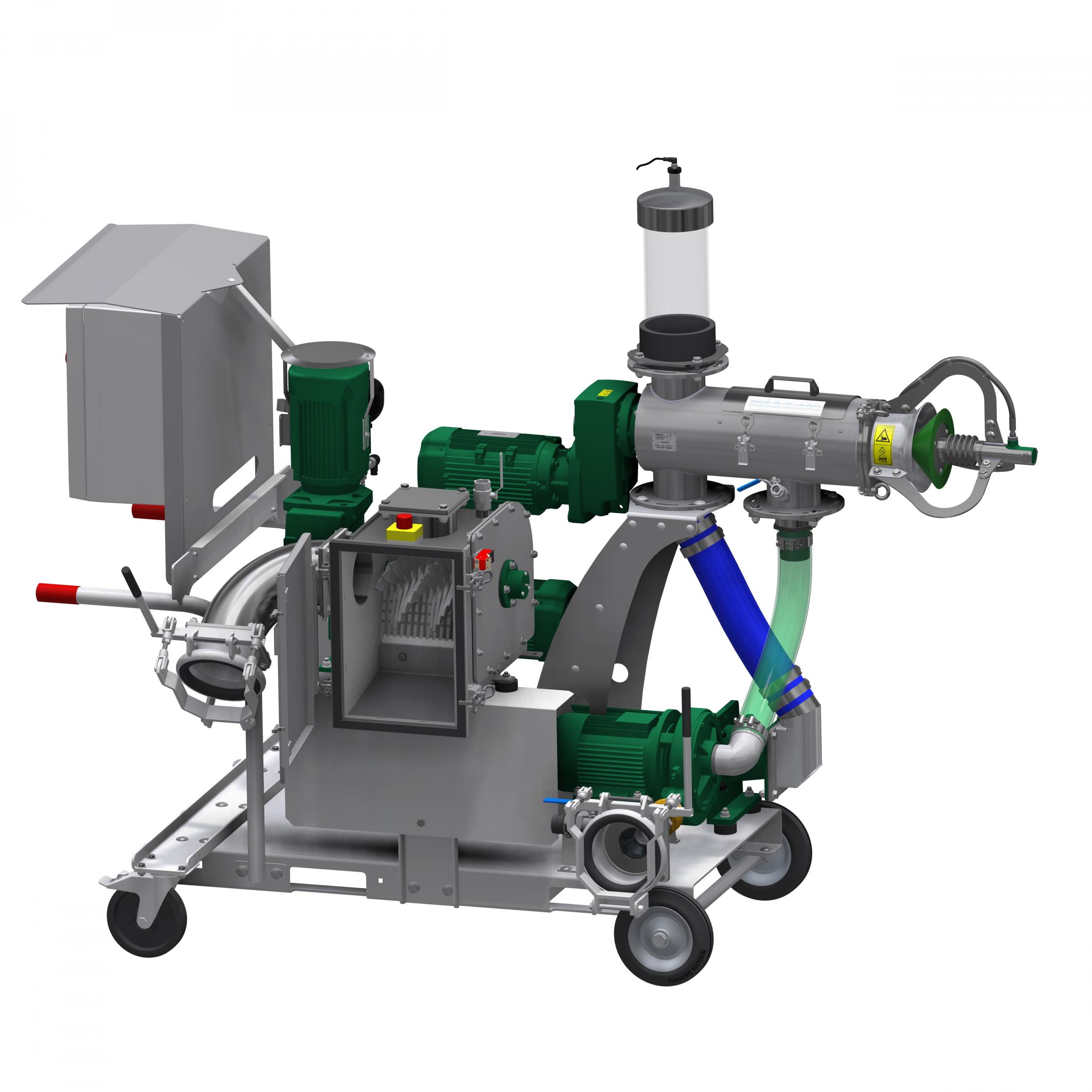

Separation is more common in Europe where farms use separators to reduce the overall slurry volume by up to 15%.

Slurry seprators are increasingly being used to split the fractions in slurry into solids and liquid to ease storage

The nutrients that are so beneficial to the land are largely retained in the liquid, so removing solids simply reduces the overall amount of slurry.

“Separated slurry is easier to spread, especially when using umbilical applicators. It also requires less agitation which saves time and investment in larger, faster mixing machines.

"A further benefit is that separated solid material with 32% or higher DM can be used for bedding,” added Mr Kitching. “Stallkamp separators start at £12,000 and there are often grants and incentives available to help purchase them."

Keeping slurry covered offers environmental and human health benefits worldwide. It also has significant agricultural benefits, offering the opportunity for farmers to make the most of slurry as a natural resource.

Well maintained, responsibly stored slurry is a cost-effective way to fertilise grassland and crops. Slurry that is covered will retain more nitrogen, making it a more valuable fertiliser.

“If farmers give this natural resource a little more time and thought it can be very valuable. Responsible slurry management is a discipline that is likely to be targeted by the government in the years to come.

"Therefore, farmers who demonstrate best practice and a willingness to improve their processes will reap the benefits,” concluded Mr Kitching.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here