A NUMBER of combine updates for the 2020 season have been announced by John Deere – with the focus on more throughput, automation and easier operation, plus a guarantee of grain sample cleanliness.

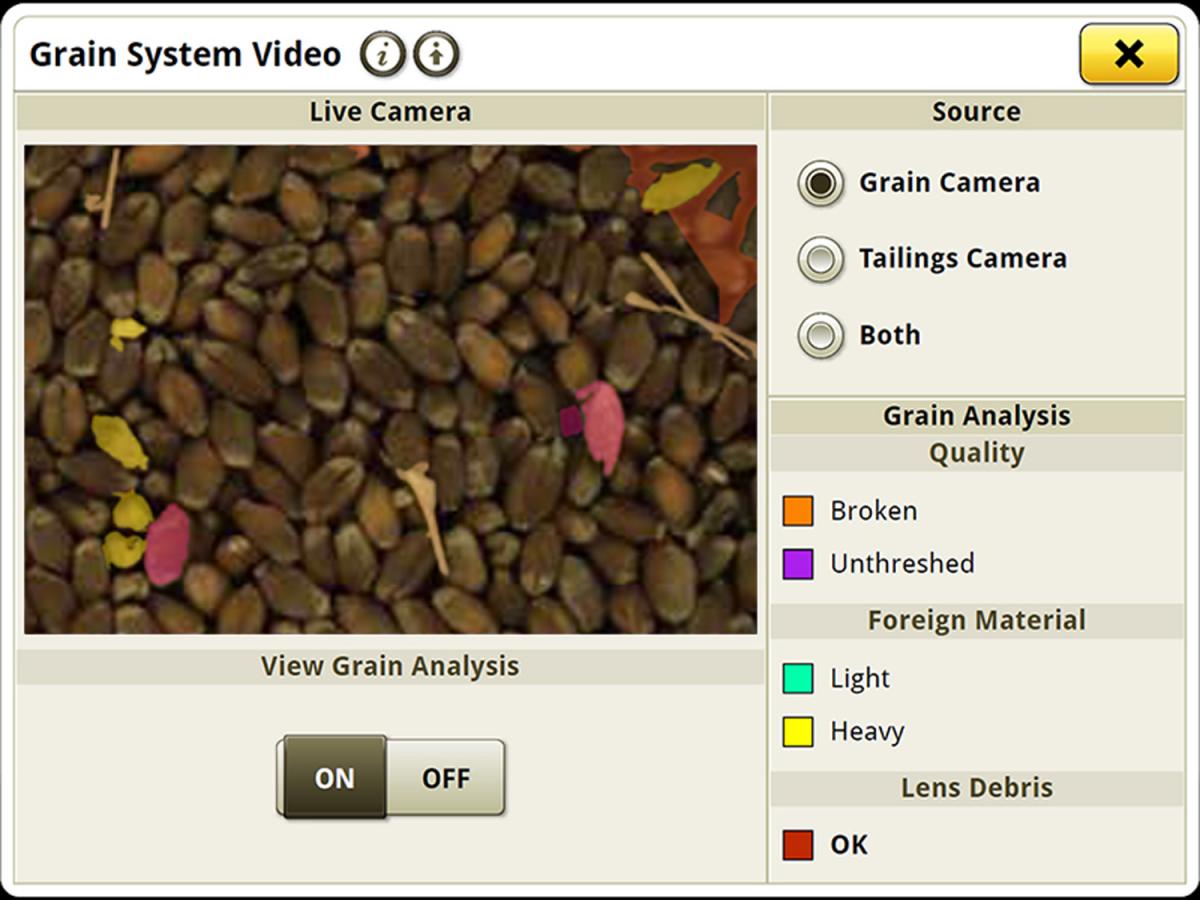

The S-Series' automatic regulation of forward speed, HarvestSmart, has been optimised and integrated with the Interactive Combine Adjustment system ICA2.

In situations where ICA2 cannot achieve the required grain sample due to high levels of chaff or broken grain, or it exceeds the set loss rate, this adjusts HarvestSmart and the combine’s speed just as the driver would normally do. At the same time, engine load is maintained at the desired level for maximum harvest efficiency.

To back up these new features, John Deere will guarantee S700 Series customers a broken grain content of less than 1% in wheat for the 2020 harvest. If the proportion is higher, the customer will receive compensation for these losses equivalent to the price per tonne of lost grain.

Side winds can have an enormous effect on the distribution chopped straw, so on S700 Series machines the angle of spread to be adjusted automatically. Using GPS, this detects the combine’s direction of travel and automatically mirrors the broadcast pattern once the combine turns at the headland and moves in the opposite direction.

Improvement in chop quality is also enabled by remote adjustment of the counter knife. With this, the operator can assess chop quality by checking the combine’s reversing camera, and set the counter knife position from the seat.

The previous introduction of the ActiveYield automatic yield sensor removed the need for manual yield calibrations and relieved the operator of the stress and time involved in waiting to get results, while also increasing their accuracy. From 2020, this system will be supplemented with an even more precise humidity sensor.

This should result in an improvement in data collection, especially for both low and high grain moisture contents. Calibration intervals plus yield and humidity data will be recorded along with other important information on the combine’s documentation software.

Connectivity now plays an important role in data collection from field operations and so now John Deere is offering wireless data transfer plus remote display access free of cost for five years.

This enables data exchange between any mobile computers and smartphones as well as the farm office via JDLink Connect.

PANEL

New display for W- and T-Series

John Deere's W and T-Series combines can now get the new fourth generation 4640 Greenstar display.

While all combine settings are still regulated using the armrest display, all other functions can also be controlled through the 4640 touchscreen. These include guidance, documentation, data transmission and MachineSync automatic steering of the tractor/trailer combination driving alongside.

The display is removable and can also operate SectionControl on a sprayer, for example.

PANEL 2

Latest headers available

The new 700X variable length header will also bew new from John Deere for 2020 use.

This maintains the existing unit’s long 1200mm table for maximum harvesting capacity and minimum losses in oilseed rape, with the benefit of better crop flow thanks to a new low-profile feeding design.

In addition, the slip clutch position has been moved directly to the auger to minimise wear and further durability improvements have been made, with 25% thicker skid plates on all units.

Recognising that combining swaths of oilseed rape, legumes and other crops, is regaining importance, John Deere will also be offering the new 615P pick-up header. This has a working width of 4.5m and is equipped with unique air-sprung support wheels. The crop is gently picked up by tines before being transferred to a horizontal belt to minimise losses.

Its large 660mm auger, with a float range of 57mm, is big enough to adapt to big crop volumes and ensure that the combine's cleaning system is constantly and evenly fed.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here