By Fiona Sloan

From starting as a summer fencing job in 2001, David Wyllie together with his brother, Stewart, now run a successful fencing business, which has grown steadily from its inception in 2010.

Their DWS Fencing business is based at Hannah Farm, near Annan, in Dumfries and Galloway and has been farmed by the family in 1929. Until 1993, the farm was run by Stewart and David’s’ father, Alasdair and his two brothers, James and Roderick, as a successful dairy in conjunction with two other farms in Dumfries-shire and Australia.

Following Alistair’s untimely death in 2011, the boys found themselves running everything, with mother Sheila, who has since retired from the business.

The farm regularly finishes 500 cattle a year and remains important to the family, but the growth of the fencing business has seen it take over as the main enterprise.

After working away from home on fencing work, David returned in 2010 to set up his own business and with Stewart on board, the partnership works well. “We work well together,” said Stewart. “Not because we are similar but because we are so different! We both have our strengths and while David is better on the practical side and managing the fencing teams, I am better on the bookwork and supplies side of things.”

Both agree that the success of the business has been dependent on being able to recruit, train and retain good staff. “We’ve been fortunate to have been kept busy, but it was the opportunity to periodically take on quality staff, that encouraged the business to grow,” added David.

“I’d rather take on someone who impresses me as a person and train them from scratch, than someone who is partially trained and has already developed pre-conceptions on what the job entails.”

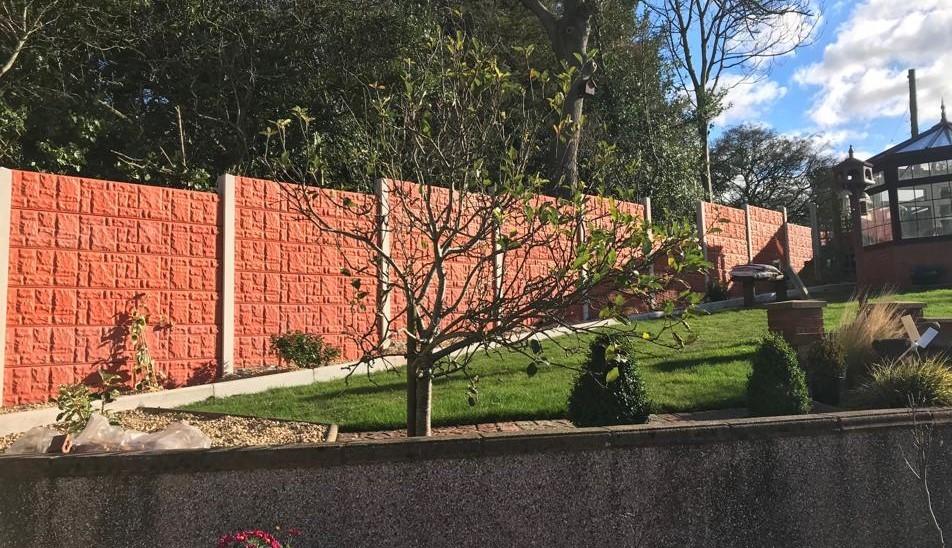

DWS Fencing has branched into many different areas, although still regards farm fencing as the bread and butter of the business. In 2015, it was tasked with building one of the largest high security fence in the country for the Home Office. This, among other diverse jobs which came along, has allowed them to branch out into other areas, through little more than word of mouth.

“The number of different things our staff can turn their hands to never ceases to amaze us and it is that quality and work ethic, which has allowed us to tackle some of the projects we have,” said Stewart.

From agricultural fencing to designing and building cladded goal posts for a local school, the business has a wide portfolio of services, including permanent and temporary, standard, electric and Clipex fencing; deer fencing, garden, equine, slurry lagoon, concrete and post and rail jobs.

They also hire out diggers and have progressed into ground preparation works, pipe and cable laying, shed erection, concreting, fabrication, drainage forestry work, including high climb work.

Having a full-time joiner allows the business to build summerhouses, school playground equipment, stables and bridges and it is regularly employed by schools, telecommunication centres and the NHS for the likes of playing fields, play equipment, paving and utility work.

They have a core staff of 11, plus three part-time administration staff and generally take on seasonal workers as labourers amounting to around 20 in the summer months.

“The business is all about the people who work for it. We pride ourselves in staff training and retention and hopefully it is partly due to pay but, more importantly, we involve them in the direction the business is taking and the purchases which we make.”

The key to the business is for the management understanding their own limitations and out-sourcing the right people. The focus is on everyone doing what they are good at and this ensures that the quality of the workmanship is maintained, which is vital to finding the next project.

Purchasing costs are part of Stewart’s remit and he maintained that if you don’t measure, you can’t mend – whether that is the cost of outputs or on purchases. “The best thing my father taught me, was the art of negotiation,” he said. “You should never back anyone into a corner to get a good outcome. Always give them two options. The success in negotiation, is getting them to choose the one you want them to.”

David’s background in farming gives him a practical understanding of the industry and design needed, whether building handling pens or sheds. His work with other commercial enterprises, however, has given him a sound understanding of the importance of risk assessment, safety and insurance.

With teams working as far away as Ullapool and Northumberland at any one time, it is vital that all aspects are considered and the safety of the staff and quality of the work is paramount. This has become even more evident, with a move into forestry work.

The necessity to ensure all bases are covered is essential, although official courses for some aspects of the job are hard to find and need to be tailored to the operation, such as operating a post driver.

It is not, however, all plain sailing. With the introduction of biomass energy generation and tax changes in the 1980’s, timber supplies are becoming increasingly difficult to source and the price of raw timber has doubled in the past year. The family like to work with local smaller sawmills as it allows them to be involved in attention to detail in the wood and the processes required.

While half the cost of putting up a fence is the labour cost, a good quality fence post will last much longer, making it much better value for money. These are options which customers can take, but the boys agree that they would always advise farmers to spend more on the posts and less on the wire if necessary, as wire rarely fails through natural wear and tear in comparison to a post. With a large range of fencing materials, many options are available

“Regardless of who is working for you,” added David, “always make sure that they have adequate insurance cover. It is important that all necessary protocols are put in place including risk assessment, method statement, health and safety policy etc. While insurance is a huge cost to our business, it is worth every penny in peace of mind for the business and its customers.”

New innovations, like the petrol driven post driver and kitting out the quad bike with carrying gear and a tool for rolling out wire, has enabled the firm to increase its output on hill work. The possible introduction of GPS control systems on equipment, which reduce downtime are a consideration for the near future.

What then of the future: “We are at a size we are comfortable with. The quality of what we do is, as important to us as it is to our customers and we wouldn’t want to dilute that by taking on more staff, that we weren’t entirely confident were up to the job,” said Stewart.

David added: “Seeing a person starting as a labourer and progressing to a fencer, then team leader, is what it is all about for us as. It brings immense satisfaction. Also, getting good feed-back from a job makes everything worthwhile and our stand at Dumfries Show every year is our way of saying thanks to our customers.”

The Inventory

Vehicles: Six Mitsubishi pickups and one Toyota pickup

Tractors: New Holland 6080, Massey Ferguson 5410, Massey Ferguson 5445 and a Massey Ferguson 5475

Fencing gear: Four Protech P300 post drivers, plus a Honda quad with Quadcrate fencing system

Other machinery: Takeuchi 1.7t digger, Takeuchi 8.5t digger, Herbst low loader, Manitou forklift, Bobcat skid steer loader and five Ifor Williams trailers.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereComments are closed on this article