Quality grass and cow welfare will always be key to profitable milk production, add to that sexed semen from high genomic sires and Patrick Morris-Eyton, looks set to take the family’s dairy enterprise at Beckside, to a new level.

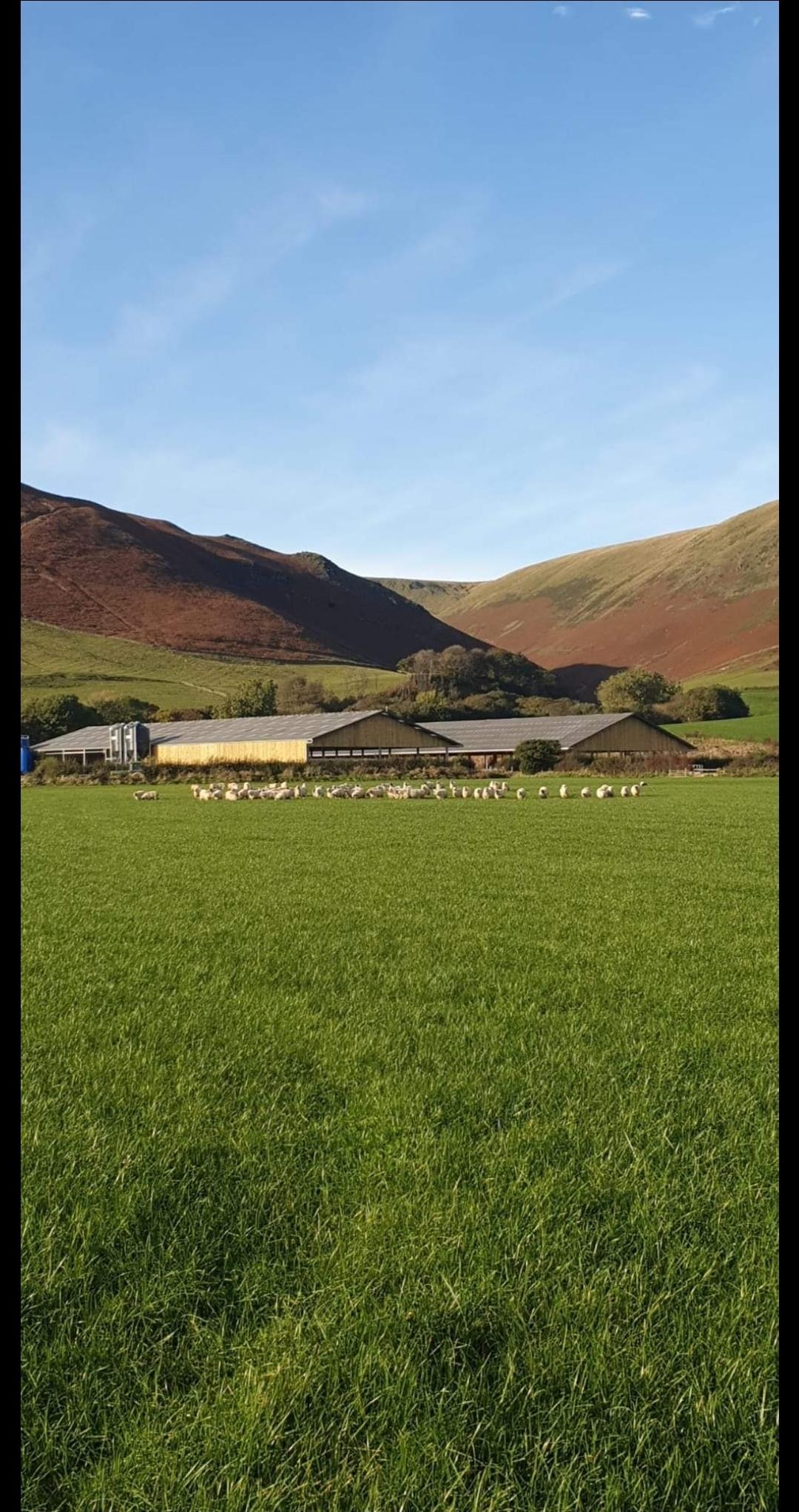

Originally a ‘sheep man’ having worked with Mary McCall Smith’s Connachan Blackface ewe flock just outside Crieff for 18months, Patrick came home to the family farm in the Lake District to take over the running of the pedigree Swaledales.

However, despite top prices of £4800 for in-lamb females and £3000 for shearling rams, he sold off his pedigree sheep in 2017 to concentrate on the family’s dairy unit comprising 300 cow pedigree Holstein herd producing rolling averages of 9500litres on a twice-daily milking regime.

“Commercially our cows were making money and they were providing a more robust income compared to the sheep which are much more hard work,” Patrick told The Scottish Farmer.

“Fell sheep can’t touch the margins from dairy cattle – even when milking through a 25-year-old parlour and housing that were holding our cows back,” he said adding that the decision was then made to sell off the lowland sheep to concentrate on updating the dairy.

Improving the quality of the ration by taking four cuts of silage instead of three coupled with enhanced welfare in the cow sheds, saw almost instant improvements in milk yields, with the following year seeing rolling yields jump to 10,400litres.

It is nevertheless the recent completion of the family’s multi-million pound investment at Beckside that Patrick believes will see the greatest improvements in production.

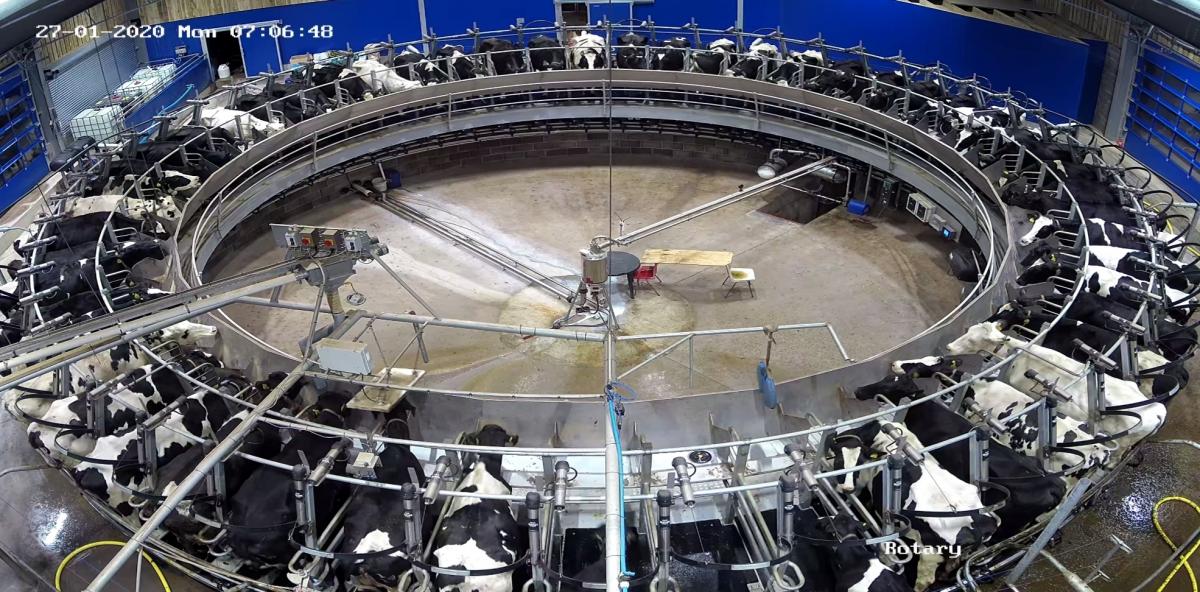

This includes an all in one open-plan 125m x 25m cow shed capable of housing 350 cows, and 72m x 25m accompanying handling unit complete with 54point Waikato rotary parlour.

Patrick added: “We were going to put in robots, but you never get away from them as someone always has to be around just in case something goes wrong. With a rotary parlour, when the milking is done, you’re finished. One person can do the milking so much faster in a rotary compared to our old Fullwood Herringbone. There is always room for expansion with a rotary too.”

Previously, one man could milk 80 cows per hour in the 25-year-old 12 x 24 herringbone parlour, but the same man can milk 200 cows in the same period in the 54pt rotary.

“The rotary has revolutionised our lives to such an extent that everyone now has a better work/home life balance,” said Patrick, who is also starting to see benefits of improved milk yields from better cow health and comfort as a result of this massive investment.

The first of the cows were milked through the rotary mid September 2019 and in the space of the last four months, digital dermatitis has been reduced from 10% of the herd to 2% as a result of the automatic foot bath after every milking.

Cows are also enjoying more comfort from 40mm foam mattresses as opposed to 30mm mattresses in the previous cubicle shed. Rubber matting throughout the rotary parlour and printed concrete instead of grooved along the walk ways and feed areas, is also lending itself to reduced falls and lameness and better signs of heat.

The new high ridged open-sided cow shed has also been shown to have better ventilation, with cleaner air leading to less bacteria, less disease, drier beds and reduced mastitis. LED lighting throughout helps to optimise cow health, which coupled with no clear roof sheets, means heat is kept out, thereby ensuring a more consistent temperature throughout the entire shed.

Patrick has also been working with sexed semen from genomic tested bulls over the past four years which has significantly improved the genetic potential of all animals born.

“We do all our own AI work and we are getting the same conception rates with sexed compared to conventional semen, which allows us to put more of our herd to a beef sire to increase the value of the resultant progeny,” he said.

At present AI is split 50:50 between dairy and beef semen, with all beef calves sold privately or through Buitelaar. All dairy heifer calves are genomic tested which at £30 per time, enables the herd to retain the best as replacements with the remainder able to be sold at premium rates.

Patrick added: “I know £30 per head sounds a lot, but it’s nothing when you think it costs anything from £1800-£2000 to take a heifer calf through to calving. Genomics have allowed us to accelerate the rate of genetic gain in our herd to such an extent that Beckside is now in the top 10% of the breed, with our youngstock in the top 5%.

“I still look to breed cows with strength, dairy quality and longevity, but I am also looking for healthy cows with improved milk yields and constituents which I can get using high genomic bulls.

“There are some genomic bulls that don’t always perform, but all have helped to improve our herd,” Patrick said adding that the lowest sire used in recent years had a PLI of £700, with the highest at £878 being the No 1 genomic bull, Bomaz Fynn.

While sires are selected on their genomic figures now, the most productive cow in the herd at present is nevertheless a Picston Shottle daughter in her ninth lactation, that has produced 12 calves during that time!

With improvements in genetics, cow welfare and comfort, Patrick is confident production will increase further with few if any cost increases and, more importantly, reduced health costs per cow.

The aim is to increase production from the current 33litres per day by almost 3litres per day now that the new improved cow comfort cow shed is fully operational which should lead to less standing time for milking, coupled with better ventilation, better lighting and therefore more lying time and less stress.

And, by moving from two to three times a day, which will reduce pressure on the cows’ udders at peak yield, milk yields should increase by another 10-15%, he said.

Costs are kept under control by continual benchmarking as part of an Arla R500 group; Arla 360; Morrisons milk contract and nutritionist benchmarks vs other clients.

FACT file

• Family partnership of Morris Eyton and Son, owned in partnership with grand-parents and parents, Robert (a land agent) and Rowena Morris Eyton and Patrick.

• Farming 630acres at Beckside which has been in the family for more than 300 years, plus common grazing on Blackcombe Fell.

• Milk 350 pedigree Holstein cows with average yield of 10,400litres in 305 days or 33litres per day; aim to increase to 400 milking cows.

• 800 breeding sheep with switch over to Highlander composite breed

• 87kw hydro electric power station.

• Patrick attained Tesco Future Farmer Foundation in 2015/16; Myerscough Young Farmers Leadership Academy in 2018; Arla Next 2018/19 and in May was elected district chairman of Arla South Lakes.

• Staff aims – take on more people to help us be the best. Move away from staff working overtime to an eight-hour day with night milking done by relief staff.

• Staff put through the correct training to include, first aid, telehandler, quad bike, spraying etc, with additional training courses openly encouraged.

ON THE spot:

* Where would you like to be in 2030? – Milking an 800 dairy cow herd with performance in the top 1% of UK herds

* Best advice ever received? – If you're standing still you are going backward

* Future of British dairy industry – Very optimistic if people are willing to embrace change

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here